Evaluating Commercial Roofing Systems: A Capital Asset Framework

Commercial roofing systems are a critical component of a building’s envelope, functioning as a primary capital asset that directly impacts operational continuity, energy expenditures, and long-term structural integrity. As a fiduciary advisor to facility managers and CFOs, we approach every roofing project not as a construction task, but as a strategic capital investment. The selection, installation, and maintenance of your roofing system directly influence your building’s valuation, tenant satisfaction, and exposure to financial risk. The total cost of ownership, which extends far beyond the initial bid, must be the primary metric for evaluating any proposal. Our role is to provide the engineering and financial clarity necessary to protect your asset and ensure predictable capital expenditures.

The Financial Liability of Deferring Roof Maintenance or Replacement

Deferring necessary roof maintenance or replacement is not a cost-saving measure; it is the accrual of unmanaged liability. Each weather event that exploits a known deficiency transforms a predictable CapEx item into a catastrophic, unbudgeted expense. The consequences extend far beyond the direct cost of repair, creating cascading financial impacts including operational downtime, irreversible inventory damage, and tenant disruption that can violate lease agreements. Furthermore, a neglected roof presents a significant premise liability risk, exposing the property owner to litigation in the event of injury caused by water intrusion. Choosing the lowest bid for a stop-gap repair is a shortsighted financial decision that fails to address the underlying asset degradation and invites these exact liabilities.

Key Performance Indicators (KPIs) for Roofing System Evaluation

A responsible capital plan requires evaluating roofing systems based on quantifiable performance metrics, not just initial cost. These KPIs are the foundation of a sound investment decision:

- Asset Lifespan: The projected service life of the system dictates its depreciation schedule and the timeline for future capital outlay. A 25-year system carries a fundamentally different financial structure than a 15-year system.

- Energy Efficiency (R-value): The R-value of the insulation and the reflectivity of the membrane surface directly correlate to HVAC operational expenses. A higher R-value is a direct investment in reducing long-term energy costs.

- Wind Uplift Rating: This engineering specification determines the system’s ability to withstand severe weather events. A higher rating can mitigate risks of catastrophic failure and may lead to more favorable insurance premiums.

- Puncture Resistance: For roofs with significant foot traffic or mechanical equipment, a higher puncture resistance rating reduces the likelihood of incidental damage, minimizing repair costs and leak potential.

- Code Compliance: Adherence to local and international building codes (IBC) is non-negotiable. Non-compliance renders a building liable for fines and may invalidate insurance claims.

Single-Ply Membrane Systems: A Comparative Analysis

Single-ply membranes represent a significant portion of the commercial roofing market, valued for their performance and installation efficiency. However, not all single-ply systems are engineered to solve the same business challenges. A thorough analysis of TPO, EPDM, and PVC is critical to aligning the material science with your facility’s specific operational demands.

Thermoplastic Polyolefin (TPO): Balancing Energy Efficiency and Heat-Welded Seam Performance

TPO is a thermoplastic single-ply membrane known for its excellent energy efficiency. Its white, reflective surface is an Energy Star-rated cool roof solution that can significantly lower cooling costs in applicable climates. The defining engineering advantage of TPO lies in its heat-welded seams. Unlike systems relying on adhesives, TPO seams are fused together with hot air to create a monolithic, waterproof barrier. This process eliminates the primary point of failure in many roofing systems—seam degradation—thereby reducing long-term maintenance liabilities. However, TPO’s formulation has evolved over the years, and a proper evaluation must ensure the specified product has a proven track record of resisting UV degradation and maintaining flexibility.

Ethylene Propylene Diene Monomer (EPDM): Lifecycle Cost Analysis for Adhered vs. Ballasted Systems

EPDM is a synthetic rubber membrane with a proven history of durability, particularly its exceptional resistance to thermal shock and UV radiation. Often referred to as “rubber roofing,” its primary vulnerability lies in its seams, which rely on adhesives and tapes. While modern adhesive technology has improved, these seams remain a maintenance focal point over the asset’s lifespan. EPDM can be installed in a fully adhered system, which is lightweight, or a ballasted system, which uses river rock or pavers to secure the membrane. A ballasted system may have a lower initial cost but adds significant dead load to the structure and makes leak detection a complex, costly forensic exercise. A fully adhered system offers superior performance and easier maintenance, representing a more prudent long-term capital investment.

Polyvinyl Chloride (PVC): Chemical and Puncture Resistance for Specialized Facilities

PVC is a premium thermoplastic membrane engineered for durability and resistance to harsh environmental conditions. Like TPO, its seams are heat-welded for superior, monolithic protection. PVC’s key differentiator is its robust chemical resistance, making it the standard specification for facilities with rooftop grease traps, such as restaurants, or those exposed to industrial chemicals and exhaust. It also offers excellent fire retardant properties and high puncture resistance. For a standard warehouse, PVC may be over-engineered; for a food processing plant or manufacturing facility, it is an essential risk management tool that protects the roofing asset from accelerated degradation.

| System Attribute | TPO (Thermoplastic Polyolefin) | EPDM (Ethylene Propylene Diene Monomer) | PVC (Polyvinyl Chloride) |

|---|---|---|---|

| Seam Technology | Heat-Welded (Monolithic) | Adhesive/Tape (Maintenance Point) | Heat-Welded (Monolithic) |

| Energy Efficiency | Excellent (Highly Reflective) | Fair (Black color absorbs heat) | Excellent (Highly Reflective) |

| Chemical Resistance | Moderate | Good | Excellent (Ideal for restaurants, industrial) |

| Projected Lifespan | 15-25 Years | 20-30 Years | 20-30+ Years |

| Primary Application | General Commercial, Retail, Warehouses | Large Footprints, Cold Climates | Industrial, Food Service, Chemical Exposure |

Multi-Ply & Metal Systems: Assessing Durability and Redundancy

For facilities where durability and operational continuity are the absolute highest priorities, multi-ply and metal systems provide an engineered solution focused on redundancy and longevity. These systems command a higher initial capital investment but offer a superior long-term ROI by minimizing maintenance CapEx and virtually eliminating the risk of catastrophic failure.

Modified Bitumen (Mod-Bit): Multi-Layer Protection and Traffic Resistance

Modified Bitumen is an asphalt-based system designed with multiple, redundant layers of protection. Typically installed in two or three-ply configurations, Mod-Bit systems offer exceptional resistance to punctures, tears, and heavy foot traffic from HVAC maintenance crews. This built-in redundancy means that a breach in the top layer does not result in an immediate leak, providing a significant safety factor that single-ply membranes cannot match. While installation can be more labor-intensive, often requiring torch-application by highly skilled technicians, the resulting roof is a robust, durable asset built to withstand demanding conditions.

Standing Seam Metal Roofing: Maximizing Longevity and Minimizing Maintenance CapEx

Standing seam metal roofing represents the pinnacle of long-term asset durability, with lifespans often exceeding 50 years. The system’s design features concealed fasteners and raised, interlocking seams that are crimped mechanically, creating a weatherproof barrier that is highly resistant to wind uplift. The panels are engineered to allow for thermal expansion and contraction, preventing fastener fatigue and maintaining structural integrity over decades. While the initial CapEx is the highest among common commercial systems, the total cost of ownership is often the lowest due to minimal maintenance requirements and an unparalleled asset lifespan. It is the definitive choice for property owners focused on maximizing long-term capital asset preservation.

Proactive Maintenance Protocols: Extending Asset Lifespan to 25+ Years

A new roof installation is not the end of a capital project; it is the beginning of an asset management cycle. Implementing a proactive maintenance program is the only responsible method to ensure warranty compliance, mitigate unforeseen repairs, and maximize the return on your initial investment. We reject the industry’s reactive repair model in favor of proactive asset preservation.

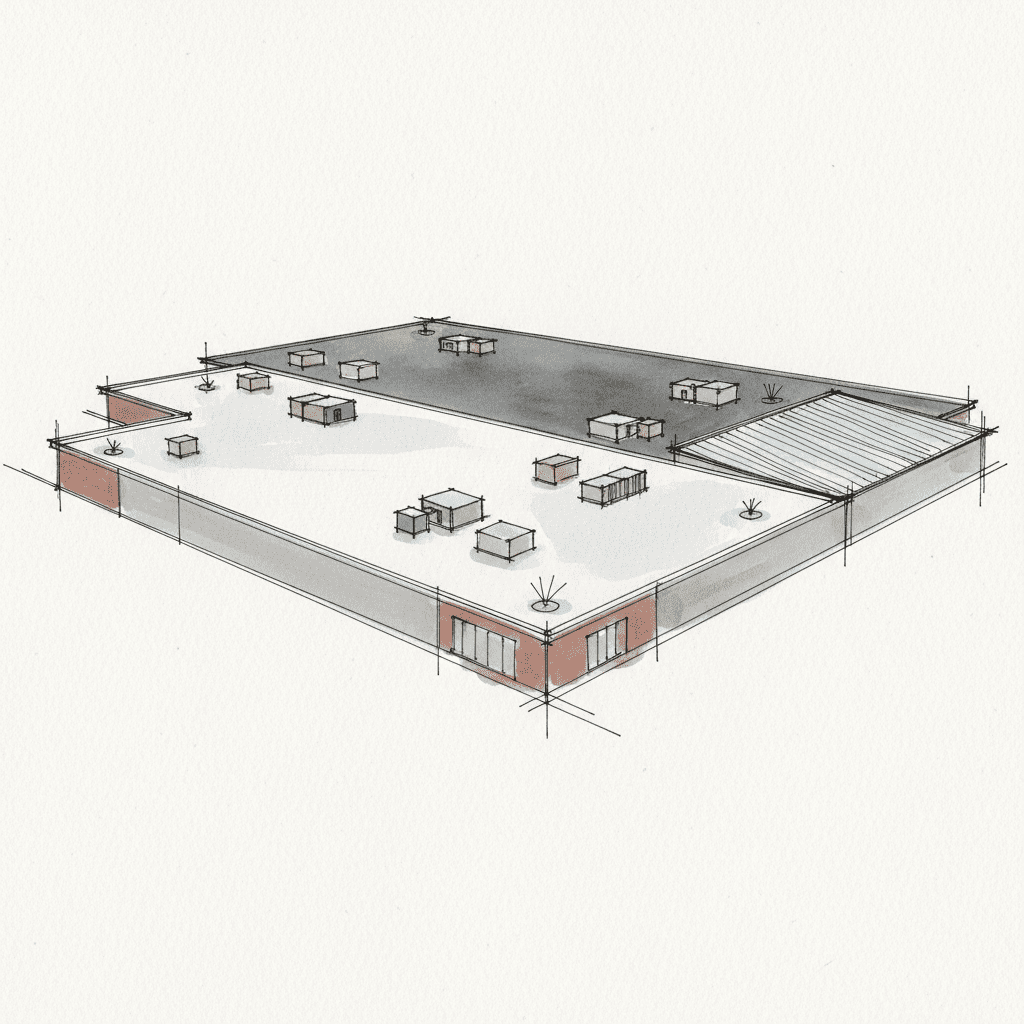

Bi-Annual Inspection SOPs: Identifying Failure Points Before They Impact Operations

Our Standard Operating Procedure involves bi-annual inspections, typically in the spring and fall, to systematically collect data on the roof’s condition. This is not a cursory walkthrough. It is a forensic analysis utilizing moisture detection tools and infrared thermography to identify subsurface moisture before it saturates insulation and compromises the deck. We meticulously document all critical failure points—flashing details, drainage systems, membrane conditions, and rooftop penetrations—to create a quantitative report. This data allows us to perform targeted, preventive maintenance that stops leaks before they can cause operational disruption.

Capital Budgeting Framework: Forecasting Repair and Replacement Costs

The data gathered from our inspections feeds directly into a capital budgeting framework. We provide a Roof Condition Index score and a multi-year financial forecast that outlines anticipated maintenance costs and a projected timeline for eventual replacement. This transforms your roofing budget from a volatile, reactive expense into a predictable, manageable line item. By providing this fiscal certainty, we empower you to make informed, proactive decisions about your capital assets, eliminating the financial chaos of emergency replacements.

Contractor Vetting: Mitigating the Financial Risk of Operational Disruption

The single greatest threat to a successful roofing project is not material failure; it is contractor failure. Selecting a commercial roofing partner based on the lowest bid is a direct invitation for operational disruption, schedule delays, and financial liability. A contractor’s core competency is not just their technical skill, but their ability to execute a complex project within an active business environment without negatively impacting your revenue-generating operations.

The True Cost of a Low-Bid Contractor: Quantifying Risks of Delays and Lawsuits

A low bid often signals deficiencies in safety protocols, insurance coverage, material quality, or labor skill. These deficiencies manifest as tangible business costs. Vague proposals lead to a barrage of change orders that destroy the original budget. A poor safety culture (high EMR) results in OSHA violations, project shutdowns, and potential lawsuits. Substandard materials and workmanship lead to premature failure and voided manufacturer warranties. The most significant cost is operational disruption—the noise, debris, and logistical chaos that alienates tenants and interrupts your business. The perceived savings of a low bid are invariably consumed by these unmanaged risks.

Verifying Credentials: Insurance, Bonding, and Manufacturer Certifications

Fiduciary duty requires a rigorous due diligence process. This is non-negotiable. Your contractor must provide current certificates for general liability and workers’ compensation insurance, naming you as an additional insured. Verify their bonding capacity to ensure they are financially stable enough to complete the project. Most importantly, confirm they hold the highest level of certification from the manufacturer of the specified roofing system. Without this certification, the manufacturer’s warranty—a key component of your asset’s value—is invalid. An EMR (Experience Modification Rate) below 1.0 is a strong indicator of a robust safety culture, which correlates directly to a well-managed, undisruptive project.

The RocStout Process: Engineering Fiscal Certainty into Your Roofing Asset

RocStout Commercial operates as a fiduciary partner, not merely a contractor. We have engineered our entire process around the two factors that matter most to asset managers: zero operational disruption and absolute fiscal certainty. Our standard operating procedures are designed to protect your tenants, your schedule, and your capital budget from the risks inherent in commercial construction.

Our Commitment to Zero Operational Disruption: A Project Management Guarantee

The true measure of a successful commercial roofing project is that your tenants barely know it’s happening. Our process begins with a comprehensive logistics and tenant communication plan. We coordinate material delivery, staging areas, and daily work schedules to minimize impact on your daily operations. Every project is managed by an OSHA 30-certified supervisor who provides daily reporting on progress and safety compliance. Our crews adhere to a strict water-tight-by-nightfall protocol, ensuring your building is secured at the end of every workday. This is not just a promise; it is a project management guarantee.

Line-Item Reporting and Multi-Year Lifecycle Planning for Predictable CapEx

We believe that fiscal certainty is born from transparency. Our proposals are not lump-sum estimates; they are detailed, line-item reports that clearly delineate the costs for materials, labor, and project management. This ‘no surprise’ billing ensures that the approved budget is the final budget. Upon project completion, our partnership evolves. We provide a comprehensive asset lifecycle plan, incorporating our bi-annual inspection data to help you forecast maintenance needs and plan for future capital expenditures. We are not here to sell you a roof; we are here to serve as your long-term partner in capital asset preservation and risk management.