Managing Debris and Site Safety During a Commercial Re-Roof: A Tenant Relations Imperative

Managing debris and site safety during a commercial re-roofing project is not a logistical line item; it is a core function of risk management and capital asset preservation. For the fiduciary asset manager, a contractor’s safety protocol is a direct indicator of their operational discipline and a predictor of the project’s impact on your revenue continuity. An unmanaged site introduces unacceptable financial liabilities, from OSHA fines and litigation to tenant disruption and irreparable damage to your reputation. The industry standard often treats safety as a burdensome afterthought, but our methodology engineers it as a foundational component of a predictable, non-disruptive capital expenditure.

Choosing a contractor based on the lowest bid is a direct assumption of risk. This decision prioritizes a short-term cost saving over the long-term fiscal health of your asset, inviting operational chaos, inventory damage, and potential lawsuits. We operate on a different principle: our rigorous safety and debris management protocols are a form of insurance, delivering the fiscal certainty that asset managers require. They are not an expense; they are an integral part of protecting your investment and ensuring your facility remains operational and profitable throughout the project lifecycle.

The Legal & Financial Framework of Site Safety Compliance

As a property owner or facility manager, you carry a fiduciary duty to protect your asset and its occupants. This duty extends directly to the oversight of third-party contractors on your property. Understanding the legal and financial ramifications of a contractor’s safety compliance—or lack thereof—is critical to mitigating liability and managing your capital asset responsibly.

OSHA Compliance: The Non-Negotiable Baseline for Contractor Vetting

The Occupational Safety and Health Administration (OSHA) and its standards, particularly OSHA 1926 for construction, are not merely guidelines; they are the legally mandated minimum standard of care. Adherence to these regulations is a non-negotiable requirement. A contractor who cannot provide a documented, comprehensive safety program aligned with the Code of Federal Regulations is demonstrating operational negligence. Vetting a contractor’s compliance history and site-specific safety plan is a fundamental step in your due diligence process. Failure to do so exposes your organization to regulatory fines and, more significantly, demonstrates a lapse in fiduciary oversight.

Quantifying the Financial Impact of Safety Lapses on Asset Value

A safety incident is never just an accident; it is a predictable financial event resulting from a failure in process. The costs cascade far beyond the immediate incident, directly impacting your balance sheet. These liabilities include:

- Increased Insurance Premiums: A single major incident can elevate your property and workers’ compensation premiums for years.

- Project Delays: An OSHA investigation can halt a project for weeks or months, delaying your return to full operational capacity and impacting revenue.

- Litigation Costs: Legal expenses from employee or third-party (tenant/visitor) injury lawsuits can be catastrophic.

- Brand Reputation Damage: An incident at your facility creates negative press and erodes tenant and customer confidence, directly affecting asset value.

Effective risk mitigation, executed through a professional roofing partner, transforms safety from a liability into a controllable factor that protects asset value.

Shared Liability: The Property Owner’s Role in Contractor Safety Oversight

It is a dangerous misconception that hiring a contractor fully transfers liability. Under the legal principle of vicarious liability, an asset owner can be held responsible for the negligent acts of their contractors. This is particularly true if the owner failed to perform adequate due diligence in vetting and selecting a qualified, safety-conscious partner. Your role in contractor safety oversight is an active one, requiring documented verification of their qualifications. This is a critical risk transference step.

| Document | Fiduciary Purpose | Red Flag |

|---|---|---|

| Certificate of Insurance (COI) | Verifies adequate General Liability, Auto, and Workers’ Comp coverage to protect your asset from claims. | Low coverage limits, expired policy, or no waiver of subrogation. |

| Site-Specific Safety Plan (SSSP) | Confirms the contractor has analyzed the specific hazards of your property and has engineered controls. | A generic, non-customized plan that doesn’t address your site’s unique features. |

| OSHA 300 Logs (3 Years) | Provides a transparent history of the contractor’s recordable injuries and incidents. | High incident rates, recurring injury types, or refusal to provide logs. |

| Competent Person Certifications | Verifies that the on-site supervisor has the required training and authority to enforce safety protocols. | Expired certifications or no designated on-site competent person. |

Core Components of a Comprehensive Roofing Safety Plan

A safety plan is more than a document; it is an operating system for managing risk. It must be built on a foundation of engineering principles, rigorous protocols, and proactive analysis. A professional plan addresses every phase of the project, from material staging to final debris removal, ensuring the protection of workers, tenants, and the physical asset.

Fall Protection Systems Analysis: Guardrails vs. Personal Fall Arrest Systems (PFAS)

Falls are the leading cause of fatalities in construction. A contractor’s approach to fall protection is the primary indicator of their safety maturity. A Job Hazard Analysis (JHA) must dictate the appropriate system. While Personal Fall Arrest Systems (PFAS) are common, they require extensive training, proper anchorage points, and a rescue plan. For many commercial roofs, engineered guardrail or warning line systems provide a higher level of passive protection, creating a controlled work zone that is inherently safer and requires less specialized user action. The selection is an engineering decision, not a matter of convenience.

Material & Equipment Staging Protocols: Preventing Structural Overload and Disruption

A commercial roof is not an infinite-capacity storage platform. The placement of materials, from new insulation bundles to heavy equipment, must be governed by a logistics plan that respects the building’s structural load-bearing capacity. An amateur contractor can easily overload a roof deck, leading to structural damage or catastrophic failure. Our standard operating procedure includes a detailed staging plan that designates storage areas, defines crane lift paths, and maps ingress and egress routes to prevent structural strain and minimize disruption to your parking lots and loading docks.

Site Access Control and Debris Management: Ensuring Tenant and Public Safety

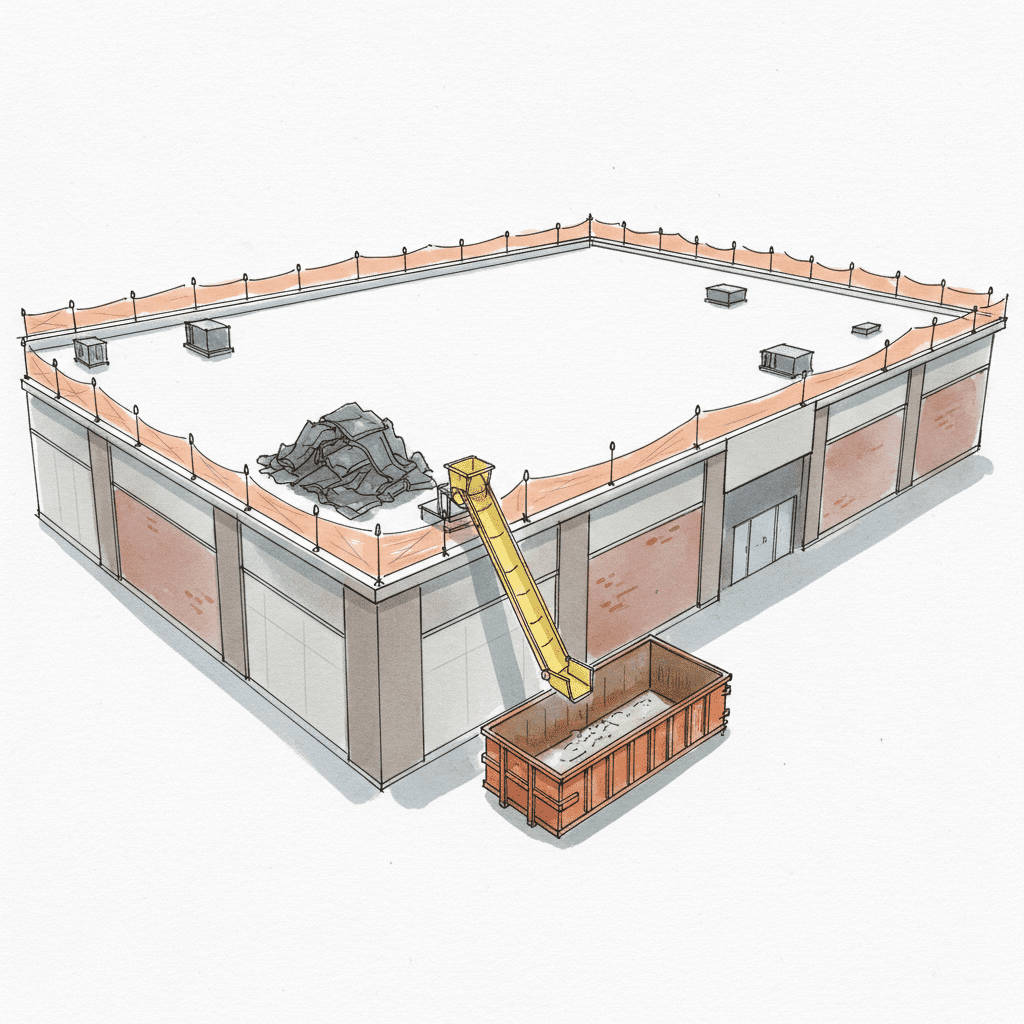

An active roofing project must be a fortress of control. Unfettered access by tenants, visitors, or the public is an unacceptable liability. Our methodology establishes a Controlled Access Zone (CAZ) around the perimeter and all roof access points. Debris management is not an ad-hoc process of throwing material off the roof edge. It requires engineered solutions like debris chutes that direct waste safely into designated dumpsters. This systematic approach to public protection and material disposal is fundamental to preventing injuries and maintaining positive tenant relations.

Emergency Action & Rescue Planning: A Mandated Contingency for Critical Incidents

Hope is not a strategy. A professional safety plan includes a mandated Emergency Action Plan (EAP) that details procedures for fire, medical emergencies, and other critical incidents. Specific to fall protection, OSHA requires a prompt rescue procedure for a worker suspended in a PFAS to prevent suspension trauma, a potentially fatal condition. A contractor who cannot produce a documented, site-specific rescue plan is non-compliant and is placing both their workers and your organization at extreme risk.

Personnel & Training Requirements: Verifying a ‘Competent Person’ On-Site

The most sophisticated safety plan is operationally useless without properly trained personnel to implement and enforce it. The human element is the critical control point. Verifying the credentials and authority of the on-site leadership is a core component of your fiduciary due diligence.

Defining the OSHA ‘Competent Person’ and Their On-Site Authority

Per OSHA, a ‘Competent Person’ is an individual who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them. In business terms, this is your on-site risk manager. They are not merely a foreman; they are a trained professional with the authority to stop work immediately—without consulting management—to correct a safety hazard. Their presence is a non-negotiable requirement for any RocStout project.

Documentation and Verification: Auditing Contractor Training Certifications

Do not take a contractor’s claims of training at face value. As part of your pre-qualification process, you must demand and audit their training records. Key certifications include OSHA 10-hour for all crew members and OSHA 30-hour for supervisory personnel. Verifying these credentials is not micro-management; it is a prudent step to ensure you are partnering with a verifiably professional organization that invests in its team’s safety and expertise.

Communication Protocols: The Role of Daily Safety Briefings in Hazard Mitigation

Safety is not a static condition. It must be reassessed and communicated daily as site conditions change. We execute daily safety briefings, or ‘toolbox talks,’ before any work begins. This is not a casual huddle. It is a structured pre-task planning session where the day’s specific tasks, associated hazards (e.g., weather changes, new materials on site), and mitigation strategies are reviewed. This procedural adherence ensures that every member of the crew is aligned on safety protocols, drastically reducing the potential for human error.

Integrating Site Safety with Operational Continuity

For a fiduciary, the true cost of a re-roofing project is not the invoice amount, but the degree to which it disrupts your business operations. A superior safety program inherently minimizes this disruption. A safe, orderly site is an efficient site, one that respects your tenants, protects your revenue stream, and aligns with your business needs.

Developing a Tenant Communication Plan to Minimize Disruptions

Silence from a contractor creates anxiety for your tenants. Proactive stakeholder management is essential. Our process includes a formal Tenant Communication Plan that acts as a roadmap for the project. It provides tenants and building occupants with clear, timely information regarding work schedules, noise expectations, changes to parking logistics, and designated safe pathways. This protocol transforms the project from an intrusion into a well-managed, professional upgrade, preserving your valuable tenant relationships.

Scheduling and Phasing: Aligning Roofing Operations with Business Needs

Your business does not stop for a re-roofing project. A sophisticated contractor understands this and builds a project schedule around your operational realities. Through careful project phasing and logistical coordination, we can schedule the most disruptive work—like crane lifts or areas with high fume potential—during off-peak hours or weekends. This alignment of the project’s critical path with your business needs is a core tenet of our commitment to zero operational disruption.

Fume, Debris, and Noise Control Strategies for Occupied Buildings

The physical byproducts of a roofing project can be a major source of tenant complaints. Mitigating them is not optional. Our standard procedures include specific control strategies, such as using low-VOC (Volatile Organic Compound) materials where possible, strategically covering or temporarily shutting down sensitive HVAC air intakes to prevent odor intrusion, and employing dust control measures. These engineering controls are designed to protect the health and comfort of your occupants and ensure business continues as usual.

The RocStout Standard: A Process-Driven Approach to Site Safety and Fiscal Certainty

We do not view ourselves as contractors; we are fiduciary partners in capital asset preservation. Our entire operational model is built on providing the fiscal certainty and risk management that property owners and CFOs require. Our approach to site safety is the ultimate expression of this commitment—a system designed to protect your people, your property, and your profitability.

Our Site-Specific Safety Plan (SSSP): A Fiduciary’s Blueprint for Risk Mitigation

We do not use generic safety manuals. Before any work begins, we develop a comprehensive Site-Specific Safety Plan (SSSP) tailored to the unique conditions of your asset. This document is a blueprint for proactive risk mitigation, outlining specific hazards, engineering controls, personnel responsibilities, and emergency procedures. It is a documented, auditable process that provides you with the assurance of compliance and transfers risk away from your organization.

Transparent Reporting and Real-Time Communication: Eliminating Surprises and Delays

Fiscal certainty is impossible without transparent communication. Our project management protocol includes daily logs, detailed progress reports, and extensive photo documentation, all accessible to you. This real-time flow of information eliminates ambiguity about project status and ensures that billing is predictable and aligned with the work completed. Our commitment to ‘No Surprise’ billing is a cornerstone of our partnership, allowing for accurate capital expenditure forecasting.

Partnering for Capital Planning: How Our Safety Protocols Protect Your Long-Term ROI

Your roof is a depreciating asset on your balance sheet. Our job is to manage that asset to maximize its lifecycle and minimize its associated liabilities. Our rigorous safety and operational protocols accomplish more than just a successful re-roofing project; they contribute to a lower total cost of ownership. By preventing costly accidents, eliminating operational downtime, and ensuring a high-quality installation, we protect the long-term ROI of your capital expenditure. Choosing RocStout is not a purchasing decision; it is a strategic capital planning decision that prioritizes operational efficiency, reduced liability, and long-term value.