The Financial Imperative of OSHA Compliance in Commercial Roofing

As a fiduciary managing a significant capital asset, your perspective on a commercial roofing project transcends materials and labor. It is fundamentally an exercise in risk management. OSHA compliance is not a contractor’s procedural burden to be delegated and forgotten; it is a core component of your asset’s financial and operational stability. Selecting a roofing partner based on their adherence to engineered safety protocols is the first and most critical step in protecting your investment, your tenants, and your balance sheet from catastrophic, and entirely preventable, liability.

Understanding OSHA’s General Duty Clause: Your Fundamental Liability as an Asset Owner

The Occupational Safety and Health Act’s General Duty Clause (Section 5(a)(1)) mandates that employers provide a workplace “free from recognized hazards that are causing or are likely to cause death or serious physical harm.” While this duty applies directly to the contractor, legal precedent and OSHA’s Multi-Employer Worksite Policy often extend liability to the controlling entity—the building owner or facility manager. Ignorance of a contractor’s unsafe practices does not grant immunity. Your fiduciary responsibility requires proactive oversight to ensure any partner operating on your asset adheres to established safety standards, such as those outlined in OSHA 1926 for construction. Failure to do so constitutes a direct assumption of risk, exposing your organization to legal and financial repercussions that far exceed the cost of the roofing project itself.

Analyzing the Financial Impact of Violations: Fines, Lawsuits, and Project Delays

Choosing a low-bid contractor who marginalizes safety is not a cost-saving measure; it is a high-risk financial gamble. A single safety violation initiates a cascade of direct and indirect costs that can cripple a capital project and impact your organization’s operational budget for years. The true cost of non-compliance is rarely confined to a single OSHA penalty. It is a compounding liability that attacks your asset from multiple fronts.

| Violation Category | Direct Financial Costs | Indirect Financial & Operational Costs |

|---|---|---|

| Fall Protection Failure | OSHA fines (up to $15,625 per violation, increasing for willful/repeat offenses), potential for six-figure litigation settlements. | Immediate project shutdown, increased insurance premiums, reputational damage, tenant disruption, legal defense fees. |

| Improper Material Handling | Costs to repair damaged property (facades, landscaping, vehicles), potential injury claims from tenants or public. | Schedule delays due to logistical failures, damage to new roofing materials, strained tenant relations. |

| Hot Work / Fire Protocol Breach | Catastrophic asset loss, insurance claim disputes, fines for lack of fire watch or proper permits. | Complete operational shutdown, business interruption losses, potential for total asset write-off. |

Documentation and Record-Keeping: Building a Defensible Safety Posture

In the event of an incident, your defense hinges on demonstrating due diligence. A contractor’s ability to provide a comprehensive, site-specific safety plan, daily toolbox talk records, equipment inspection logs, and training certifications is not administrative overhead; it is your first line of defense against liability. This documentation serves as verifiable proof that safety protocols were not just implied, but systematically implemented and enforced. At RocStout, we consider this documentation a non-negotiable project deliverable, providing you with a complete compliance file upon project completion to fortify your risk management records.

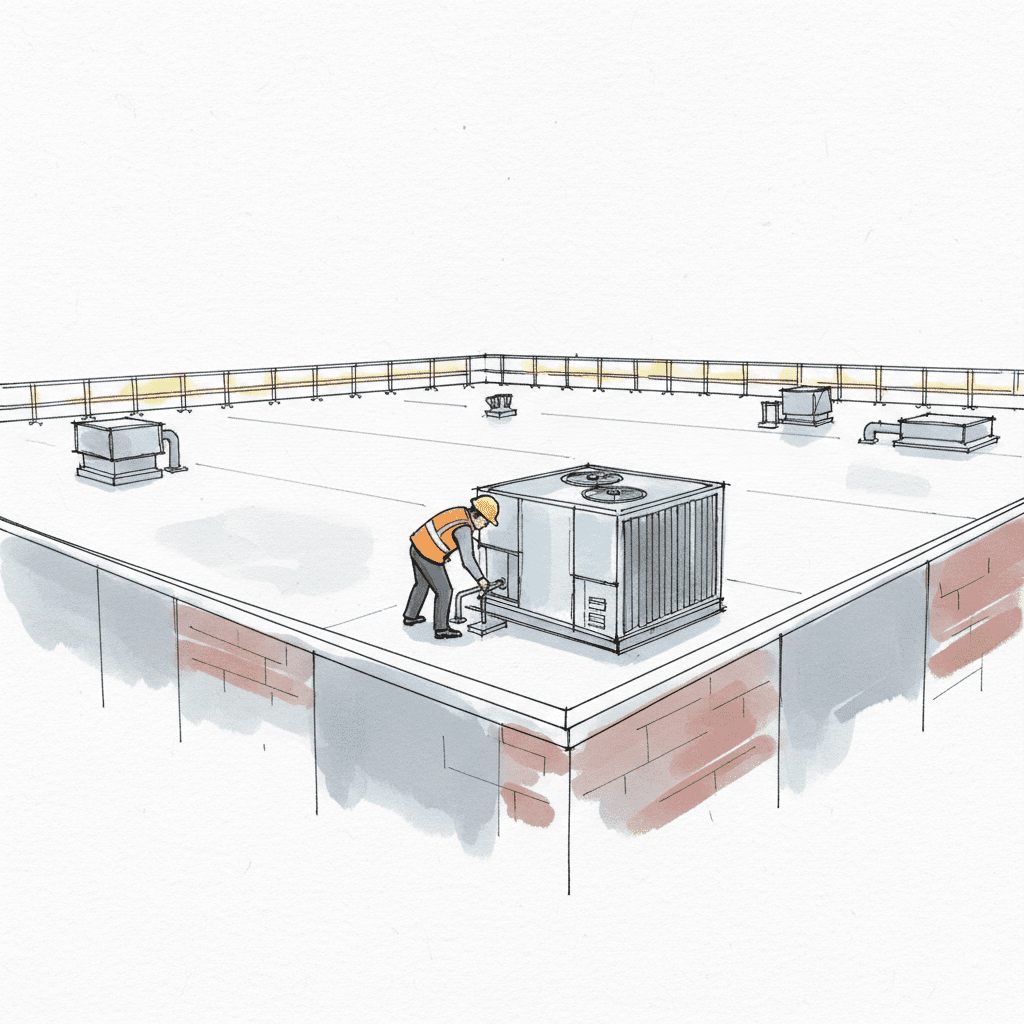

Fall Protection Systems: A Non-Negotiable Component of Asset Protection

Falls remain the leading cause of fatalities in construction. Therefore, a contractor’s fall protection methodology is a direct indicator of their operational discipline and your project’s risk profile. An engineered approach to fall protection is not merely about compliance; it’s about eliminating the single greatest threat to your personnel, schedule, and financial stability during a roofing project.

Perimeter Guardrail Systems vs. Personal Fall Arrest Systems (PFAS): A Cost-Benefit Analysis

The choice between passive and active fall protection systems is a critical business decision. A Personal Fall Arrest System (PFAS)—a harness and lanyard system—is an active system that relies 100% on individual user competence and consistent adherence. It introduces variables, including improper fit, incorrect anchorage, and complacency, which increase risk. In contrast, a perimeter guardrail system is a passive, engineered control. Once erected, it protects all personnel on the roof without requiring individual action. While potentially having a higher initial setup cost, guardrails increase project efficiency, reduce the potential for human error, and provide a superior level of collective protection, lowering the total cost of risk for the asset owner.

Roof Openings and Skylights: Mitigating High-Risk Zones to Prevent Catastrophic Failure

Unprotected skylights, roof hatches, and HVAC curbs are unacceptable liabilities. From an engineering perspective, these are classified as openings through which a fall can occur. Standard operating procedure dictates that these zones must be protected by rated covers or guardrail systems capable of withstanding forces specified by OSHA. Allowing a contractor to work around these hazards with mere caution tape is a direct violation of safety standards and an invitation for disaster. Our protocol mandates the immediate abatement of these hazards before any other work commences.

Training and Certification Audits: Vetting Contractor Competency and Reducing Your Exposure

Verifying a contractor’s safety qualifications is a crucial step in risk transference. We mandate that you demand proof of training and certification for every crew member, especially the designated on-site “Competent Person.” This individual, as defined by OSHA, must have the training and authority to identify and immediately correct hazards. Requesting and auditing these records is a standard part of our pre-deployment process. A partner who cannot produce these documents instantly is signaling a systemic failure in their safety program and should be disqualified from bidding on your capital project.

Material Handling and Site Logistics: Preventing Operational Disruption and Property Damage

The true cost of a poorly run commercial roofing project is often measured in operational disruption. A contractor’s failure to manage site logistics is a direct threat to your tenants’ operations, your property’s condition, and your project’s timeline. Our methodology treats the entire site—from the curb to the roof edge—as a managed environment where efficiency and safety are engineered into the workflow.

Establishing Secure Staging and Loading Zones to Protect Property and Personnel

A roofing project requires a carefully planned logistical footprint. Our process begins with defining a secure, isolated zone for material staging, crane operations, and debris removal. This plan protects your landscaping, pavement, and building facade from damage. We establish clear load paths and ground protection measures to ensure the structural integrity of underlying surfaces. This foresight prevents the costly collateral damage and tenant complaints that are hallmarks of a disorganized, low-bid operation.

Hot Work and Fire Prevention Protocols: Mitigating Thermal Risks to Building Assets

Any roofing operation involving torches, heat welders, or hot asphalt (bitumen) presents a significant fire risk. A professional contractor mitigates this risk through rigid adherence to a hot work permit system. This non-negotiable protocol includes maintaining a dedicated fire watch during and after operations, ensuring appropriate fire suppression equipment is staged and ready, and clearing combustible materials from the work area. To treat this as anything less than a critical safety mandate is gross negligence.

Debris Management and Disposal: Maintaining a Clean and Uninterrupted Operational Environment

A disorganized work site is an unsafe and inefficient work site. Our standard procedure includes systematic debris management, often utilizing contained debris chutes and daily site cleanups. This commitment to cleanliness is not about aesthetics; it minimizes trip-and-fall hazards for workers, prevents material damage to tenant property below, and communicates a standard of professionalism that reflects well on your management. It is a vital component of ensuring operational continuity for the businesses within your asset.

The Impact of Safety on Insurance, Liability, and Long-Term Asset Value

A contractor’s safety program has a direct and measurable impact on your organization’s financial health. The metrics used by insurance underwriters to evaluate risk are the same metrics you should use to evaluate a potential roofing partner. A disciplined approach to safety is a leading indicator of a disciplined approach to quality, which ultimately determines the long-term ROI of your roofing asset.

How a Contractor’s EMR (Experience Modification Rate) Directly Affects Your Risk Profile

The Experience Modification Rate (EMR) is a critical financial metric issued by the insurance industry to quantify a company’s safety history. A rate of 1.0 is the industry average. A contractor with an EMR below 1.0 has a proven track record of safety, resulting in lower insurance costs for them—and a significantly lower risk profile for you. Conversely, an EMR above 1.0 indicates a history of frequent or severe incidents, marking them as a high-risk partner. Demanding a contractor’s current EMR is a fundamental step in financial due diligence. RocStout maintains a premier EMR as a core component of our value proposition: fiscal certainty.

Contractual Indemnification and Certificates of Insurance: Transferring Risk Through Rigorous Vetting

Your contract and the contractor’s Certificate of Insurance (COI) are the legal instruments for transferring project liability. However, these documents are only as strong as the company behind them. A robust indemnification clause, or “hold harmless” agreement, should be standard. Furthermore, the COI must be scrutinized for adequate coverage limits, including general liability, workers’ compensation, and umbrella policies. We provide a comprehensive, transparent insurance portfolio that meets or exceeds the requirements for Class A commercial properties, ensuring you are protected.

The Correlation Between Safety Protocols and Roof System Longevity

The discipline required to maintain an impeccable safety record is the same discipline that ensures roofing materials are installed precisely to manufacturer specifications. A crew that takes shortcuts on safety will invariably take shortcuts on installation details—improper seam welding, inadequate fastener patterns, or poor flashing work. These deficiencies, while not immediately visible, create latent failures that drastically shorten the lifespan of your roofing asset and invalidate manufacturer warranties. Investing in a safety-first partner is a direct investment in quality control and the long-term performance of your capital expenditure.

Implementing a Risk Management Framework: The RocStout Standard Operating Procedure

We reject the reactive, corner-cutting approach that defines the commercial roofing industry. Our value is delivered through a process-driven methodology that provides fiscal certainty and eliminates operational disruption. This is our Standard Operating Procedure—a system engineered to protect your asset as if it were our own.

Our Mandate: The Site-Specific Safety Plan (SSP) as a Non-Negotiable Deliverable

Before a single boot steps onto your roof, we deliver a comprehensive SSP. This document is not a generic template; it is an engineered plan tailored to the unique conditions of your building. It details everything from crane lift paths and fall protection anchor points to emergency response procedures and tenant communication protocols. This plan is the foundation of a predictable, safe, and efficient project execution.

Daily Toolbox Talks and Pre-Task Planning: A System for Proactive Hazard Abatement

Our commitment to safety is a daily, process-driven discipline. Every morning, our crews conduct mandatory toolbox talks to review the specific tasks and hazards for that day. This constant reinforcement transforms safety from a manual into a shared operational culture, empowering every team member to identify and mitigate risks before they can escalate into incidents.

Transparent Reporting and Communication: Ensuring Zero Operational Surprises for Your Tenants and Management

As a fiduciary partner, we understand that your greatest liability is the unknown. Our project management framework is built on a foundation of transparent, proactive communication. You will receive regular, detailed updates on progress, adherence to schedule, and any necessary logistical adjustments. We coordinate directly with your facility management to ensure tenant activities are minimally impacted. This is the core of our “No Surprise” guarantee—providing you with the fiscal certainty and operational continuity required to manage your capital asset effectively.