Foundational Planning: Aligning Project Scope with Capital Asset Strategy

A capital roofing project represents a significant, long-term investment in your building’s financial viability, and its execution demands a management framework designed to eliminate operational disruption and guarantee fiscal certainty. For the fiduciary asset manager, the roof is not merely a component of the building; it is a depreciating asset with direct impacts on operational costs, tenant satisfaction, and balance sheet liabilities. The initial planning phase is therefore the most critical stage for mitigating risk. It moves the project from a reactive, cost-based decision to a proactive, data-driven investment strategy. Miscalculations here result in budget overruns, change orders, and unforeseen operational shutdowns—liabilities that a professionally managed asset cannot tolerate.

Initial Roof Condition Analysis: Data-Driven Scoping and Budgeting

Before any capital is allocated, a comprehensive forensic analysis is the standard operating procedure for any responsible asset manager. This is not a cursory visual inspection; it is an engineering-level assessment designed to provide objective data for scoping and budgeting. We reject subjective estimates in favor of empirical evidence. This process includes core sampling to verify the existing assembly’s composition and condition, infrared thermography to produce a quantifiable moisture map of trapped water within the system, and structural load calculations to ensure the deck can support the specified system without compromising building integrity. This data forms the bedrock of a precise Project Scope Statement, eliminating the guesswork that leads to costly mid-project change orders and establishing a baseline for fiscal certainty.

Lifecycle Cost Analysis (LCA): Justifying CapEx Beyond Initial Bid Price

The lowest initial bid is almost universally the most expensive option over the asset’s lifecycle. A proper Capital Expenditure justification requires a Lifecycle Cost Analysis (LCA) that models the Total Cost of Ownership (TCO). This financial model moves the conversation from short-term cost to long-term Return on Investment (ROI). The analysis must factor in projected maintenance costs, energy efficiency modeling (e.g., kW/h savings from a reflective membrane), and the Net Present Value (NPV) of different system options. For example, a slightly higher initial investment in a thicker membrane or a fully adhered system may yield a significantly lower TCO through reduced repair frequency, superior weather resilience, and lower energy expenditures. This is how a roofing decision is transformed from an expense into a strategic capital investment that enhances asset value.

Defining the Project Charter: Establishing Milestones, Deliverables, and Governance

A commercial roofing project must be managed with the same rigor as any other major corporate initiative. A Project Charter is the foundational governance document that codifies this approach. It is not merely a scope of work; it is a formal agreement defining key stakeholders, communication protocols, Key Performance Indicators (KPIs), and a preliminary Risk Register. The Charter establishes a clear governance structure, detailing who has authority for approvals and how disputes will be resolved. It sets forth measurable milestones and deliverables tied to the payment schedule, ensuring that capital is only released upon verified performance. This document makes accountability absolute and provides the framework for transparent project oversight, protecting the owner from ambiguity and contractor negligence.

Contractor Procurement: A Framework for Mitigating Financial and Operational Liability

The procurement process is a due diligence exercise in liability mitigation, not a race to the bottom on price. Selecting a contractor is the single greatest point of risk in any capital project. A low-bid contractor who operates with inadequate insurance, poor safety protocols, or a history of litigation introduces unacceptable financial and operational liabilities onto your balance sheet. Our fiduciary responsibility is to advise clients on how to procure a partner, not just a vendor. This requires a stringent evaluation framework that prioritizes financial stability, documented safety performance, and contractual compliance over the initial price tag.

Evaluating Bids Beyond Price: Analyzing Safety Records (EMR) and Insurance Coverage

The most revealing metric on any bid package is not the price, but the contractor’s Experience Modification Rate (EMR). An EMR below 1.0 indicates a safety record superior to the industry average; a rate above 1.0 signifies a higher-than-average incident rate and, consequently, higher risk. We mandate the submission of OSHA 300 logs as objective proof of safety performance. Furthermore, we analyze the Certificate of Insurance (COI) to verify adequate General Liability and Umbrella Policy limits, ensuring they are sufficient to protect your asset from catastrophic events. A contractor with minimum-level coverage is a direct threat to your financial stability. Financial solvency, confirmed through bonding capacity or financial statements, is another non-negotiable criterion to ensure the contractor can complete the project without lien-related complications.

| Evaluation Metric | Low-Bid Contractor (High Liability) | Fiduciary Partner (Risk Mitigation) |

|---|---|---|

| EMR (Safety) | Above 1.0 (Higher risk of incidents, delays, lawsuits) | Below 1.0 (Proven safety protocols, lower liability) |

| Insurance Coverage | State minimums, leaving the owner exposed | $5M+ General Liability with Umbrella Policy |

| Project Management | Reactive, poor communication, schedule-driven by convenience | Proactive, daily reporting, schedule-driven by client needs |

| Material Submittals | Often substituted with cheaper, non-specified materials | Strict adherence to architectural specs, full transparency |

| True Final Cost | Low initial bid + multiple change orders + cost of delays | Guaranteed Maximum Price (GMP) with line-item clarity |

Technical Specification and Submittal Review: Ensuring Material and Engineering Compliance

The architectural specifications are legally binding engineering documents, not suggestions. A rigorous submittal process is required to verify that the materials being installed match the specifications precisely. This involves a detailed review of material data sheets, wind uplift calculations, and building code compliance documentation for every component of the roof assembly. This step prevents contractors from engaging in ‘value engineering’ that benefits their bottom line at the expense of your asset’s long-term performance. Ensuring compliance at the submittal stage is a critical control point that protects the integrity of the engineering design and the validity of the manufacturer’s warranty.

Contractual Safeguards: Stipulating Penalties for Delays and Non-Compliance

The contract is your primary tool for enforcing performance and mitigating financial risk. It must be structured to protect the owner, not the contractor. Key provisions include a liquidated damages clause that stipulates specific financial penalties for each day the project runs past the agreed-upon substantial completion date. A robust indemnification clause must hold the owner harmless from any claims arising from the contractor’s negligence. The contract should also clearly define the change order process to prevent scope creep and budget overruns, and establish a clear schedule of values to link payments directly to verified work-in-place. These contractual safeguards provide the legal and financial leverage necessary to compel contractor performance and maintain project control.

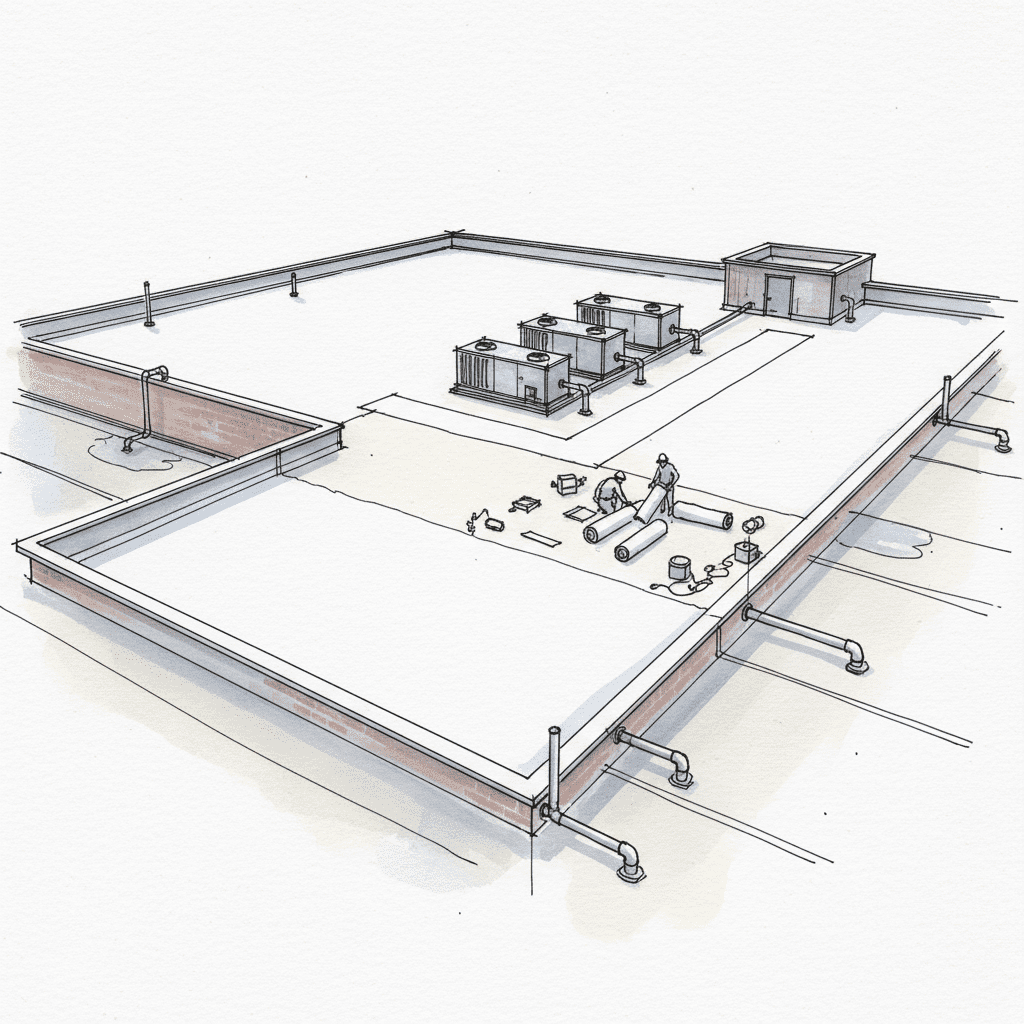

On-Site Execution: Protocols for Minimizing Operational Disruption

The true cost of a roofing project is not measured by the invoice alone, but by the degree of disruption to your core business operations. Tenant complaints, employee safety hazards, and unexpected shutdowns carry significant financial and reputational costs. Therefore, on-site execution must be governed by a rigid, process-driven methodology centered on one primary objective: zero operational disruption. This requires meticulous logistics planning, proactive communication, and an unwavering commitment to OSHA compliance. The enemy is the industry’s standard level of negligence; our standard is to operate as an invisible, seamless extension of your facility management team.

Implementing a Tenant Communication Plan: Proactive Notifications and Issue Resolution

The vast majority of tenant issues are preventable with a professional communication protocol. Prior to mobilization, a formal Tenant Communication Plan must be established and distributed. This plan details the project schedule, including specific dates and times for potentially disruptive activities such as material loading, periods of high noise, or work that generates fumes. It provides contact information for a dedicated on-site project manager who can address concerns in real-time. Daily activity reports sent to facility management ensure that you are never caught unprepared for tenant inquiries. This proactive approach transforms a potential source of conflict into a demonstration of professional management.

OSHA Compliance and Site Safety Management: Protecting Tenants, Staff, and Your Balance Sheet

An OSHA violation is not just a regulatory infraction; it is a leading indicator of a poorly managed project and a direct financial threat. A stop-work order can delay a project for weeks, while a single on-site incident can trigger lawsuits, insurance premium hikes, and severe brand damage. Our standard operating procedure mandates a Site-Specific Safety Plan for every project, which includes detailed protocols for fall protection, hazard communication, and site containment. Daily ‘toolbox talks’ reinforce these protocols. We view OSHA compliance not as a goal, but as the absolute minimum standard. A safe site is a productive, predictable, and financially secure site—the only kind acceptable for a capital asset.

Real-Time Progress Tracking vs. Project Schedule: Identifying and Mitigating Delays

Hope is not a project management strategy. Fiscal certainty is achieved through constant, data-driven oversight of the project schedule. We utilize Gantt charts and the Critical Path Method (CPM) to map out all project dependencies and establish a clear timeline. This schedule is not a static document; it is a dynamic management tool. Daily progress is tracked against planned milestones, with any deviations identified immediately. This allows for proactive resource allocation and implementation of weather contingency plans before a minor delay can cascade into a major budget overrun. This level of transparency provides stakeholders with a real-time understanding of project status and reinforces financial predictability.

Project Closeout & Asset Integration: Verifying Long-Term Performance

A project is not complete when the last screw is installed; it is complete when the new roof is fully integrated into your long-term asset management strategy. The project closeout phase is a formal process of verification, documentation, and handover that ensures the asset will perform as specified and that your investment is protected for its full service life. This phase transitions the roof from a capital project to a performing asset on your books, complete with the necessary warranties, maintenance plans, and documentation to maximize its ROI.

The Punch List Process: A Zero-Defect Approach to Final Project Acceptance

Substantial completion is not final acceptance. The punch list process is the final quality assurance gate. It involves a meticulous inspection of the entire roofing system by the owner’s representative, the consultant, and the manufacturer’s technical inspector. Every deviation from the specifications, no matter how minor, is documented. Final payment and release of retainage are contingent upon the successful remediation of every single punch list item. This zero-defect approach enforces the highest standard of quality and ensures that you receive precisely the system you invested in, free of deficiencies that could compromise its long-term performance.

Warranty Documentation and Asset Management Handover: Securing Your Investment

A warranty is only as valuable as the documentation supporting it. We ensure the delivery of a comprehensive closeout package, the centerpiece of which is the manufacturer’s No Dollar Limit (NDL) warranty. This is the highest grade of warranty, covering both materials and workmanship without a cap on financial liability. The package also includes all Operations and Maintenance (O&M) Manuals, as-built drawings, and final, unconditional lien waivers from all contractors and suppliers. This handover formally transfers a fully documented, unencumbered, and warrantied asset to your portfolio, ready for integration into asset management software.

Establishing a Proactive Maintenance Program: Maximizing the Asset’s Service Life

The single most effective way to maximize the service life of your new roofing asset is to implement a proactive roof asset management plan from day one. Relying on reactive repairs is a financially inefficient strategy that shortens asset life and leads to predictable failures. A structured maintenance program, including bi-annual inspections, debris removal, and seam and drainage integrity checks, is essential. This not only preserves the asset’s condition but is also a mandatory requirement for keeping the manufacturer’s NDL warranty in full force. Proactive maintenance is a low-cost operational expense that protects a high-value capital asset.

The RocStout SOP: A System for Engineering Fiscal Certainty in Roofing Projects

The industry’s standard approach—ambiguous bids, unpredictable schedules, and disruptive on-site behavior—is unacceptable to any serious asset manager. We have engineered a system of Standard Operating Procedures (SOPs) designed to replace financial uncertainty with fiscal predictability. Our methodology is built for the CFO and Facility Manager who measure success in terms of ROI, operational continuity, and risk mitigation. We are not simply contractors; we are fiduciaries in the capital planning process.

Our Pre-Construction Financial Analysis: No-Surprise, Line-Item Budgeting

We operate on a principle of total cost transparency. Our process begins with a detailed financial analysis that results in a line-item budget, often structured as a Guaranteed Maximum Price (GMP). This eliminates the risk of ambiguous allowances and surprise change orders. We present clear options, including value engineering proposals that enhance long-term performance rather than simply cutting initial costs. This allows for seamless integration into your capital budget forecasting and provides the fiscal certainty required for executive-level financial planning.

Our Daily Reporting Protocol: Total Transparency for Fiduciary Stakeholders

Effective governance requires timely, accurate information. Our stakeholders are provided access to a cloud-based portal that serves as a single source of truth for the project. This dashboard is updated daily with photo documentation of work completed, manpower logs, and a clear visualization of progress-to-date against the project schedule. This protocol provides an unprecedented level of transparency, allowing you to monitor your capital investment in real-time from anywhere, ensuring complete alignment and accountability without requiring your physical presence on-site.

Our Zero-Disruption Commitment: A Multi-Point Plan for Tenant and Operations Continuity

We understand that time is money, and operational disruption is a direct threat to your revenue. Our Zero-Disruption Commitment is not a goal; it is a process-driven system. It is the core of our on-site execution and is designed to make our presence virtually invisible to your tenants and operations.