R-Value as a Key Performance Indicator for Building Assets

For a fiduciary asset manager, R-value is not an abstract engineering metric; it is a direct input into your building’s operating expense model. It quantifies the thermal resistance of your roof assembly—its capacity to impede heat flow. A higher R-value translates directly into a more stable interior environment, reduced energy consumption, and greater control over a significant line item in your operational budget. Conversely, an improperly specified or degraded R-value represents a persistent and escalating financial drain, forcing your HVAC systems into a state of continuous overexertion to compensate for an inefficient building envelope.

Translating Thermal Resistance into Operational Expense Reduction

The primary function of a high-performance roof insulation system is to minimize heat transfer. During colder months, it prevents expensive heated air from escaping; during warmer months, it blocks solar heat gain from penetrating the building. This thermal regulation has a direct, quantifiable impact on HVAC run-times and peak load demand. By engineering a roof assembly with the optimal R-value for your climate zone, we effectively reduce the operational burden on your mechanical systems. This not only lowers monthly utility expenditures but also extends the service life of expensive HVAC equipment, mitigating future capital replacement costs. This is not about simple savings; it is a strategic reduction of ongoing operational costs and a tangible enhancement of your asset’s net operating income (NOI).

Analyzing R-Value Degradation and Long-Term Thermal Drift

A critical misstep in capital planning is assuming the ‘Day One’ R-value remains static throughout the asset’s lifecycle. Many common insulation materials, particularly polyisocyanurate (polyiso), experience a phenomenon known as thermal drift. Over time, the insulating gases within the foam cells slowly diffuse and are replaced by air, causing a gradual degradation of the material’s stated R-value. This performance decay must be factored into any legitimate lifecycle cost analysis. Engaging a contractor who specifies materials based solely on initial R-value, without accounting for aged thermal performance, is prescribing a future of diminishing returns and escalating energy costs. Our standard operating procedure involves specifying materials and assembly designs that deliver stable, predictable thermal performance over a 20- to 30-year horizon, ensuring your initial investment continues to perform as projected.

Navigating R-Value Mandates and Building Code Compliance

Building codes, specifically the International Energy Conservation Code (IECC) and its state or municipal derivatives, are not suggestions; they are legal mandates that establish the minimum acceptable thermal performance for your building asset. Viewing these regulations as a mere checklist to satisfy a building inspector is a profound financial miscalculation. These codes represent the baseline for energy efficiency, and compliance is a fundamental aspect of risk management. Failing to meet or exceed these standards exposes your organization to significant liability and operational disruption.

Mapping IECC Climate Zones to Minimum R-Value Requirements

The IECC divides the country into distinct climate zones, each with a prescriptive minimum R-value requirement for commercial roofing. For example, the mandate for a facility in Dallas (Zone 3) is substantially different from one in Chicago (Zone 5). A contractor without a deep understanding of these specific, and often locally amended, requirements can inadvertently specify a non-compliant system. This oversight can halt a project during inspection, trigger costly tear-offs and rework, and create significant scheduling delays that disrupt tenants and operations. We view code compliance not as a target, but as the starting point for engineering a system that maximizes your asset’s long-term financial performance while guaranteeing regulatory approval.

The Liability of Non-Compliance: Financial and Legal Ramifications

Choosing the lowest bid from a contractor who overlooks or misinterprets energy code mandates is a direct assumption of risk. A failed building inspection results in a stop-work order, immediately halting progress and introducing unpredictable costs and delays. This is the definition of operational disruption. Beyond the immediate financial impact of remediation, non-compliance can affect your building’s certificate of occupancy, insurability, and future sale potential. In a litigation-prone environment, a non-compliant roof assembly can be cited as evidence of negligence, creating legal exposure. Our process-driven methodology treats code compliance as a non-negotiable deliverable, documented and verified to protect your capital investment from legal and financial liability.

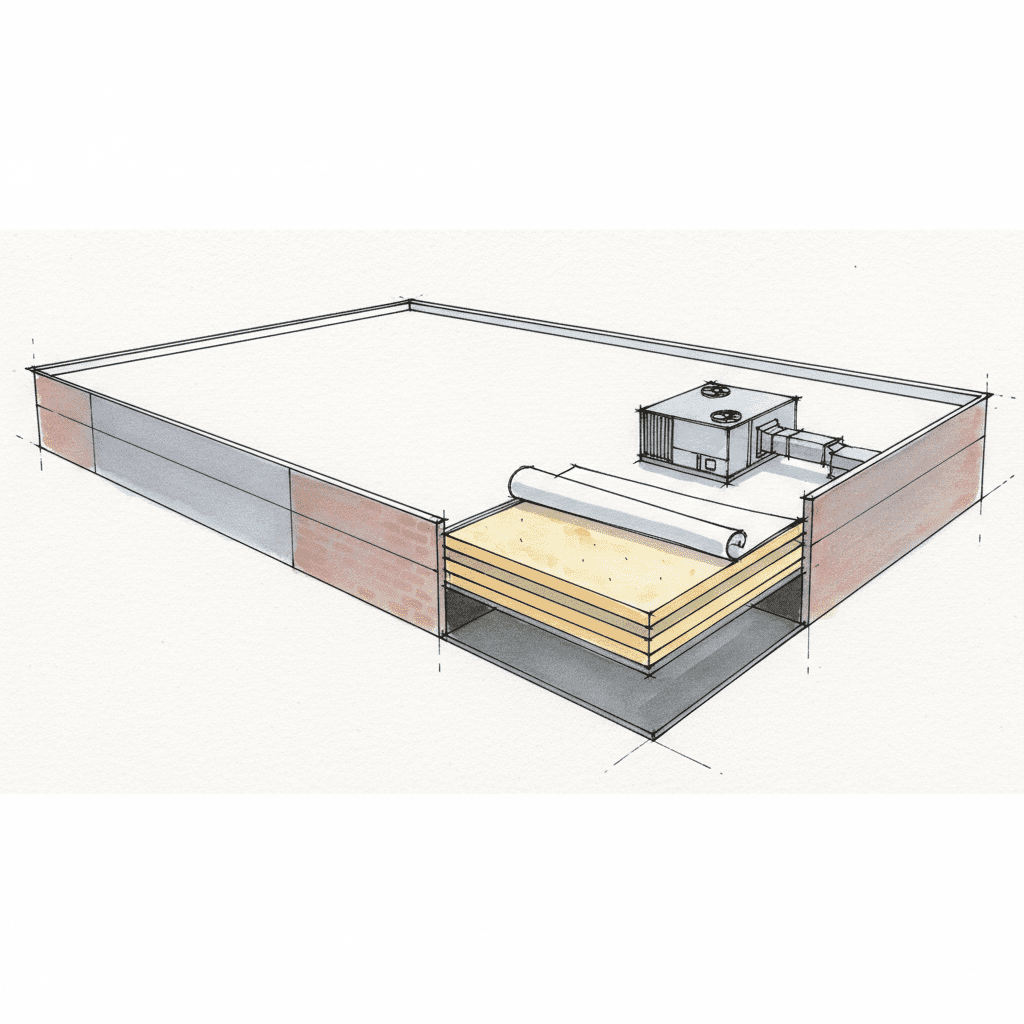

Comparative Analysis of Commercial Roof Insulation Systems

The selection of insulation material is a critical capital decision that dictates the long-term performance, durability, and cost profile of your roof asset. A fiduciary approach demands a clear-eyed analysis of the primary options, weighing their thermal efficiency against their structural properties and lifecycle stability. The following table provides a business-focused comparison of the most common commercial insulation systems.

| Insulation Type | Typical R-Value (per inch) | Compressive Strength | Moisture Performance | Financial Profile |

|---|---|---|---|---|

| Polyisocyanurate (ISO) | R-5.7 to R-6.5 | Good (20-25 PSI) | Vulnerable if facer is damaged | Highest efficiency per inch; industry standard for performance. |

| Extruded Polystyrene (XPS) | R-5.0 | Very Good (15-100 PSI) | Excellent resistance (closed-cell) | Durable, stable R-value; preferred for high-traffic or demanding environments. |

| Expanded Polystyrene (EPS) | R-3.6 to R-4.2 | Variable (10-60 PSI) | Can absorb water over time | Lowest cost per R-value; higher risk of long-term performance degradation. |

Polyisocyanurate (ISO): Maximizing R-Value Per Inch

Polyiso is the predominant insulation choice for commercial roofing due to its high R-value per inch, allowing for code-compliant assemblies without excessive thickness. This is a critical advantage when dealing with height restrictions like parapet walls and rooftop equipment curbs. Its foil-faced composition also functions as a radiant barrier. However, its performance is contingent on a completely dry system. Our protocols mandate stringent moisture detection and vapor barrier specification to protect the long-term integrity of any ISO-based system.

Extruded (XPS) vs. Expanded (EPS) Polystyrene: A Cost-Benefit Analysis

While both are polystyrene foams, XPS and EPS offer distinctly different value propositions. XPS has a closed-cell structure, providing superior resistance to moisture absorption and maintaining a more stable long-term R-value. Its higher compressive strength makes it suitable for roofs with significant foot traffic or heavy equipment. EPS provides the lowest cost-per-inch of R-value, but its open-cell structure makes it more susceptible to water absorption, which can catastrophically degrade its thermal performance. For a fiduciary, the higher initial cost of XPS often represents a more prudent long-term investment by mitigating the risk of performance loss.

The Strategic Role of Cover Boards in System Longevity and Fire Rating

A cover board is a thin, durable substrate installed over the primary insulation layer. This is not an optional upgrade; it is an essential component for asset protection. The cover board shields the softer insulation from impact damage (dropped tools, hail), distributes loads from foot traffic, and is critical for achieving the required UL fire rating for the entire roof assembly. Forgoing a cover board to reduce initial cost is a classic example of short-term thinking that jeopardizes the durability, safety, and warranty of a multi-million-dollar asset.

Quantifying the ROI of Optimal Roof Insulation

A properly engineered roofing system is not an expense; it is a capital investment with a measurable return. The decision to move beyond minimum code requirements to an optimal insulation value should be driven by a clear financial model. Our role as a fiduciary advisor is to provide you with the data needed to make a financially sound decision based on lifecycle cost analysis, not just initial bid price.

Calculating Energy Savings and HVAC Load Reduction

Our process begins with energy modeling to project the financial impact of various R-value scenarios. By analyzing your building’s geometry, climate zone, and current utility costs, we can provide a reliable forecast of annual energy savings. A higher-performance envelope can often lead to a reduction in the required tonnage for HVAC systems during a future replacement cycle, creating an opportunity for significant capital expenditure avoidance. This moves the discussion from a simple payback period to a comprehensive analysis of total financial impact.

Lifecycle Cost Analysis: Initial Investment vs. Long-Term Asset Value

The lowest bid almost always corresponds to the highest total cost of ownership. A substandard system invites premature failure, frequent repairs, and escalating energy bills, eroding any initial savings within the first few years. We provide a transparent lifecycle cost analysis that models the initial investment against projected energy savings, maintenance costs, and the expected service life of the system. This allows you to evaluate the project based on its long-term contribution to asset value and operational efficiency, which is the only responsible methodology for capital planning.

Leveraging Rebates and Tax Incentives for Insulation Capital Projects

Significant financial incentives exist to reward property owners for investing in energy efficiency. Federal tax deductions, such as Section 179D, along with local utility rebates and state-level programs, can substantially reduce the net cost of a capital project. Navigating these programs requires specialized knowledge. We act as your partner in identifying and securing these incentives, directly improving the project’s ROI and accelerating the payback period.

Mitigating Risks Associated with Improper Insulation Specification

An improperly designed or installed insulation system is a latent liability. The defects may not be visible upon completion, but they will manifest as escalating energy costs, moisture intrusion, and ultimately, premature system failure. The most severe risks are not technical; they are financial, threatening business continuity and the structural integrity of the asset.

Thermal Bridging: Preventing Hidden Energy Loss at Fasteners and Joints

Thermal bridging occurs when highly conductive materials, like metal fasteners or gaps between insulation boards, create a path for heat to bypass the insulation layer. A single fastener can create a thermal short circuit, and across thousands of fasteners, this results in significant, hidden energy loss that undermines the specified R-value. Our standard procedure mandates designs that provide continuous insulation, using staggered board layers and thermally broken fasteners to eliminate these weak points and ensure the system performs as engineered.

Moisture Infiltration: Protecting Insulation from Value-Destroying Saturation

Water-saturated insulation has an R-value of nearly zero. Its presence is catastrophic. Moisture can enter a system through poor detailing or be generated internally through condensation if a proper vapor barrier is not specified for the building’s use and climate. Once wet, insulation not only loses its value but also traps water against the structural deck, accelerating corrosion and decay. Our engineering protocol includes a thorough dew point analysis to determine the precise vapor barrier requirements, protecting your investment from this silent and destructive threat.

The Financial Cascade of a Sub-Standard System: From Inventory Loss to Litigation

The ultimate cost of a failed roofing system is never the price of the roof itself. It is the cost of business interruption. It is the value of inventory destroyed by a leak. It is the cost of tenant disruption, lease concessions, and potential litigation. It is the structural damage to the building that goes far beyond the membrane. Choosing a contractor based on the lowest price is a gamble with your entire operation. It is an explicit acceptance of risk that no prudent fiduciary would endorse.

Our Protocol for Insulation as a Capital Asset Preservation Strategy

RocStout Commercial does not install roofs; we deploy engineered systems designed to preserve capital and ensure operational continuity. Our methodology is built on providing the fiscal certainty required for effective asset management. The following protocol is our non-negotiable standard for all projects.

This disciplined, two-phase process ensures that every decision is backed by data and every action is designed to mitigate risk. It is the only responsible way to manage critical building infrastructure. By aligning our engineering with your financial objectives, we deliver a roofing asset that provides not just shelter, but a predictable and positive return on investment.