The Financial Liability of Neglected Roof Flashings

Proactive commercial roof flashing maintenance is a capital preservation strategy engineered to eliminate the primary source of water ingress—which accounts for 90% of all roof leaks—thereby safeguarding asset value and ensuring operational continuity. For the fiduciary asset manager, viewing this not as a simple repair but as a critical risk mitigation protocol is fundamental. The integrity of your roof flashing is directly correlated to the predictability of your capital expenditures and the stability of your operations. Neglecting these critical transition points on your roof system is not a cost-saving measure; it is an invitation for systemic failure, operational disruption, and significant financial liability.

The Financial Impact of Flashing Failure: From Water Ingress to CapEx Volatility

A compromised roof flashing is the initial breach in your building envelope’s defense. The subsequent water ingress initiates a cascade of financial consequences that extend far beyond the initial point of failure. This is not a maintenance issue; it is a threat to your asset’s balance sheet value and operational revenue.

Quantifying the Cost of Deferred Maintenance: Water Damage, Mold, and Structural Degradation

Deferring flashing maintenance introduces uncontrolled variables into your capital plan. An initial, manageable repair cost quickly multiplies as water saturates insulation, degrades structural decking, and fosters mold growth. A lifecycle cost analysis consistently demonstrates that the expense of remediation—which includes mold abatement, replacement of tenant improvements, and potential structural repairs—is exponentially higher than proactive maintenance. This reactive spending destroys capital and undermines the structural integrity of the asset you are mandated to protect.

Operational Downtime Analysis: Tenant Complaints, Inventory Loss, and Business Interruption

The most immediate and damaging cost of flashing failure is business interruption. For facility managers and property owners, this translates directly to tenant complaints, potential lease breaches, and a decline in tenant retention. For business owners, it means damaged inventory, production shutdowns, and compromised supply chains. Each hour of downtime represents a direct loss of revenue and a potential liability for failing to provide a safe, operational environment. RocStout’s methodology is built around the principle of zero operational disruption because we understand that your primary function is running a business, not managing a construction site.

Compliance and Liability: How Flashing Failure Breaches Building Codes and Leases

A persistent roof leak is more than an inconvenience; it is a potential breach of compliance. Tenant lease agreements typically mandate that the landlord provide a dry, secure space. Failure to do so can lead to legal liability and rent abatement claims. Furthermore, unaddressed water ingress can create conditions that violate building codes and, critically, can void your manufacturer’s roof warranty. A low-cost, non-compliant patch from an unqualified contractor to fix a flashing can nullify a multi-million dollar warranty, leaving you entirely exposed to the full cost of a future system failure.

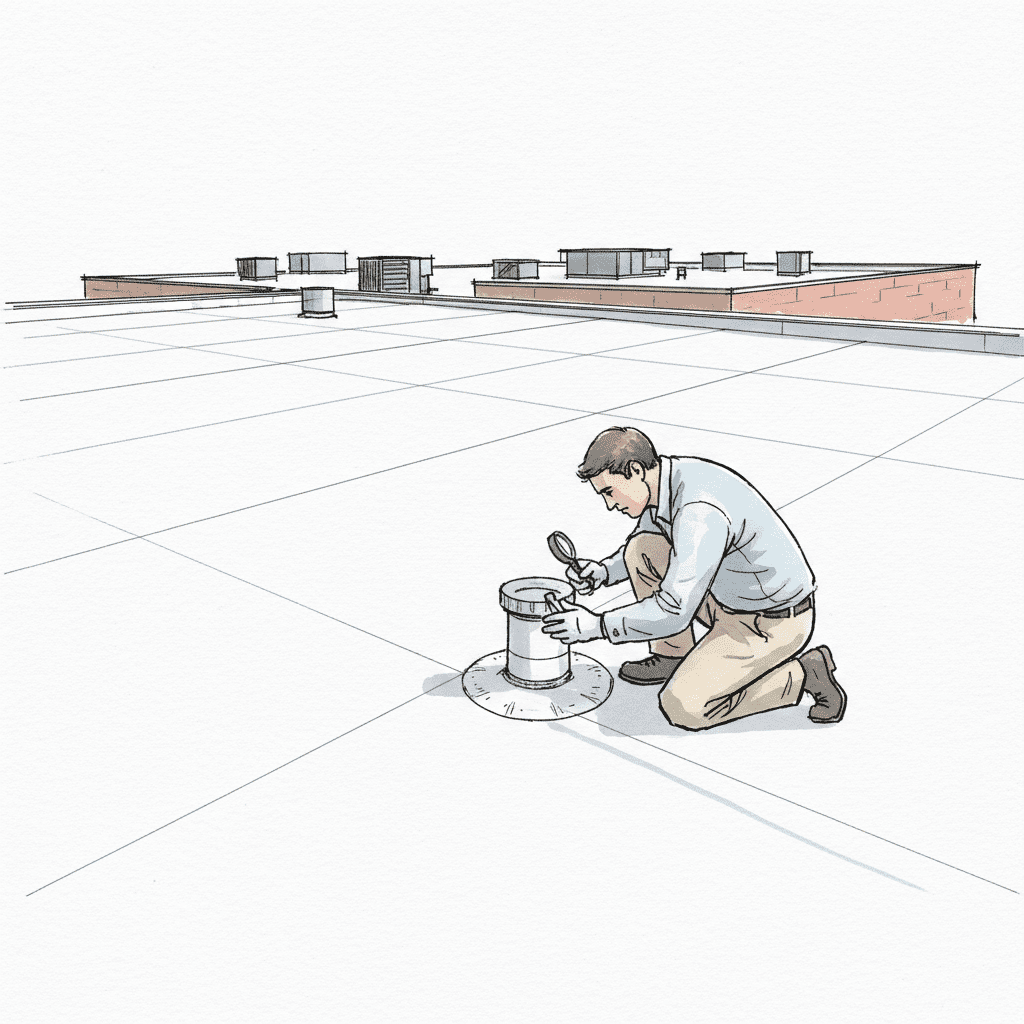

Root Cause Analysis: A Forensic Approach to Identifying Flashing Vulnerabilities

To effectively manage an asset, you must first understand its inherent vulnerabilities. RocStout employs a forensic, engineering-based diagnostic process to identify the root cause of flashing failure. We do not treat symptoms; we identify and correct the underlying geometric, material, and physical stressors that lead to water ingress. This is the only responsible methodology for ensuring long-term performance and fiscal certainty.

Diagnosing Failures at Critical Transition Points: Parapets, Vents, and HVAC Curbs

The overwhelming majority of leaks originate where the flat roof plane transitions to a vertical surface or a penetration. These locations—parapet walls, HVAC curbs, vents, and drains—are the most complex areas of a roof system. Proper engineering requires a multi-component system of termination bars, counter-flashing, and compatible sealants to accommodate differential movement. Failure is almost always a result of improper installation or the natural degradation of materials at this critical roof-to-wall interface. Our diagnostic process meticulously inspects these points of failure to develop a precise, targeted repair protocol.

Material-Specific Degradation Patterns: Metal, TPO, EPDM, and Modified Bitumen

Different roofing materials have distinct failure modes. Our technicians are trained to identify these material-specific patterns:

- TPO/PVC: Failures typically occur at the seams due to improper hot-air welding techniques, leading to seam voids that allow water intrusion.

- EPDM: This material is susceptible to shrinkage over time, which exerts constant pulling tension on flashing details at curbs and walls, eventually causing sealant failure or membrane tearing.

- Modified Bitumen: Open seams and granule loss from UV degradation are common failure points. Flashing details can become brittle and crack with age.

- Metal: Corrosion at fastener points, failed gaskets on screws, and breakdown of sealant at joints are the primary vulnerabilities, particularly where soldered joints were not executed to specification.

The Physics of Failure: Thermal Expansion, Contraction, and Membrane Stress

A commercial roof is in a constant state of flux, expanding and contracting with daily thermal cycles. This movement exerts immense stress on flashing materials and sealants. Over time, this thermal expansion can cause fasteners to back out, sealants to lose elasticity and adhesion, and membranes to fatigue. Combined with wind uplift forces that pull at the roof’s perimeter and corners—where most flashings are located—these physical stressors create the conditions for inevitable failure if not proactively managed.

A Comparative Analysis of Commercial Flashing Repair Methodologies

As a fiduciary, your choice of repair methodology directly impacts the long-term financial performance of your asset. The industry is saturated with contractors offering low-cost, temporary patches that fail to address the root cause of the problem. This approach is a financial liability, not a solution.

Short-Term Patching vs. Systemic Repair: A Lifecycle Cost Comparison

The allure of a low initial cost for a ‘band-aid’ fix is a dangerous fiscal trap. While a systemic repair requires a greater initial capital outlay, its total cost of ownership is significantly lower. Reactive maintenance cycles create unpredictable expenses and guarantee future operational disruptions. A systemic, engineered repair provides a long-term, warrantable solution that preserves capital and stabilizes your maintenance budget.

| Metric | Low-Bid ‘Patch’ Repair | RocStout Systemic Repair |

|---|---|---|

| Initial Capital Outlay | Low | Moderate |

| Total Cost of Ownership (5-Year) | High (due to repeat failures and subsequent damage) | Low (single, durable expenditure) |

| Risk of Operational Disruption | Very High | Eliminated |

| Impact on Warranty | High risk of voiding manufacturer warranty | Maintains or enhances warranty compliance |

| Fiscal Certainty | None; invites unpredictable future spending | High; provides a predictable, warrantable asset |

Engineering Standards for Thermoplastic (TPO/PVC) and EPDM Flashing Repair

Correctly repairing modern single-ply membranes is a science. For TPO and PVC systems, all new flashings must be attached using hot-air welding to create a monolithic, waterproof bond. The use of incompatible sealants or adhesives is a direct violation of engineering specifications. For EPDM systems, repairs demand meticulous surface preparation with specified primers and the use of pressure-sensitive or vulcanized seam tapes to ensure proper adhesion. These are not suggestions; they are standard operating procedures required to restore the integrity of the system.

Protocols for Metal and Bituminous Flashing System Restoration

Legacy systems require their own set of rigorous protocols. Metal flashing repairs often necessitate mechanical fastening, the use of butyl sealants for proper joint sealing, and in some cases, soldering to create a permanent waterproof seam. For bituminous systems, repairs must be executed with compatible asphaltic compounds and reinforcement fabrics, applied via torch or cold-process adhesive according to the manufacturer’s details to ensure a durable, watertight bond.

The RocStout Standard Operating Procedure (SOP) for Flashing Repair

We reject the standard contractor model of reactive, unpredictable service. Our Standard Operating Procedure is a process-driven methodology designed to deliver fiscal certainty and eliminate operational disruption for asset managers. We function as a partner in your capital planning process, not simply as a vendor.

Ultimately, proactive flashing maintenance is a fundamental component of responsible asset management. It is a strategic decision to trade the high risk of unpredictable, catastrophic failure for the controlled cost of planned, preventative action. This approach protects your asset, your tenants, and your budget from the significant liabilities of water intrusion. Contact RocStout to implement a flashing maintenance program that aligns with your fiduciary responsibilities and ensures the long-term financial health of your commercial property.