The Critical Role of Edge Metal in Commercial Asset Protection

Commercial roof edge metal and coping are engineered perimeter systems designed to prevent wind-related structural failure and water intrusion, thereby protecting the building envelope and preserving the long-term value of the capital asset. As a fiduciary advisor, it is our responsibility to state unequivocally: the most common point of failure on a commercial roof is an improperly designed or installed edge metal system. This is not an aesthetic trim component; it is a critical structural element that dictates the performance and longevity of your entire roofing assembly. Choosing a low-bid contractor who treats it as an afterthought is a direct invitation to catastrophic loss, operational disruption, and significant legal liability.

Analyzing Wind Uplift Forces: The Primary Failure Point for Commercial Roofs

During a significant wind event, the perimeter and corners of a commercial roof experience the highest negative pressure, or wind uplift. According to engineering standards like ASCE 7, these forces can be several times greater than the pressure on the main field of the roof. When an under-engineered edge metal system detaches, it creates a peeling effect, allowing wind to get underneath the roof membrane. This initiates a chain reaction that can lead to the complete failure of the roofing system, exposing your building’s interior, inventory, and tenants to the elements. This is not an unforeseen accident; it is a predictable outcome of failing to adhere to mandatory engineering protocols. The liability for the resulting damage—both structural and operational—falls squarely on the asset owner who failed to ensure compliance.

Ensuring Water Intrusion Prevention at the Building Perimeter

Beyond wind resistance, edge metal and coping serve as the final line of defense against water intrusion at the most vulnerable part of the building envelope: the termination point. A properly fabricated and installed system manages water flow, directing it away from the building facade and preventing moisture from infiltrating behind the wall system. Failures in flashing, sealant, or seams at the perimeter lead to persistent, hard-to-diagnose leaks. These leaks result in costly inventory damage, the potential for mold growth, and the degradation of structural components, all of which disrupt operations and diminish asset value.

The Financial and Legal Implications of Non-Compliant Edge Metal Systems

Specifying and installing a non-compliant edge metal system is a significant financial and legal misstep. In the event of a failure, insurance carriers will investigate the cause. If the installed system does not meet the standards required by local building codes or the manufacturer’s warranty—specifically ANSI/SPRI ES-1—claims are frequently denied on the grounds of negligence. This leaves the asset owner responsible for the full, unplanned capital expenditure of a replacement roof and associated interior damages. As a facility manager or CFO, exercising your fiduciary duty requires ensuring that all components, especially these critical perimeter details, are specified and installed to meet or exceed established engineering standards. Anything less is a calculated risk with no corresponding reward.

Engineering Specifications for Common Edge Metal Profiles

A compliant, high-performance roof perimeter is not an accident. It is the result of precise engineering, fabrication, and installation of specific metal profiles designed to counter known failure points. RocStout’s standard operating procedure mandates the use of systems that adhere to strict performance criteria, ensuring your asset is protected.

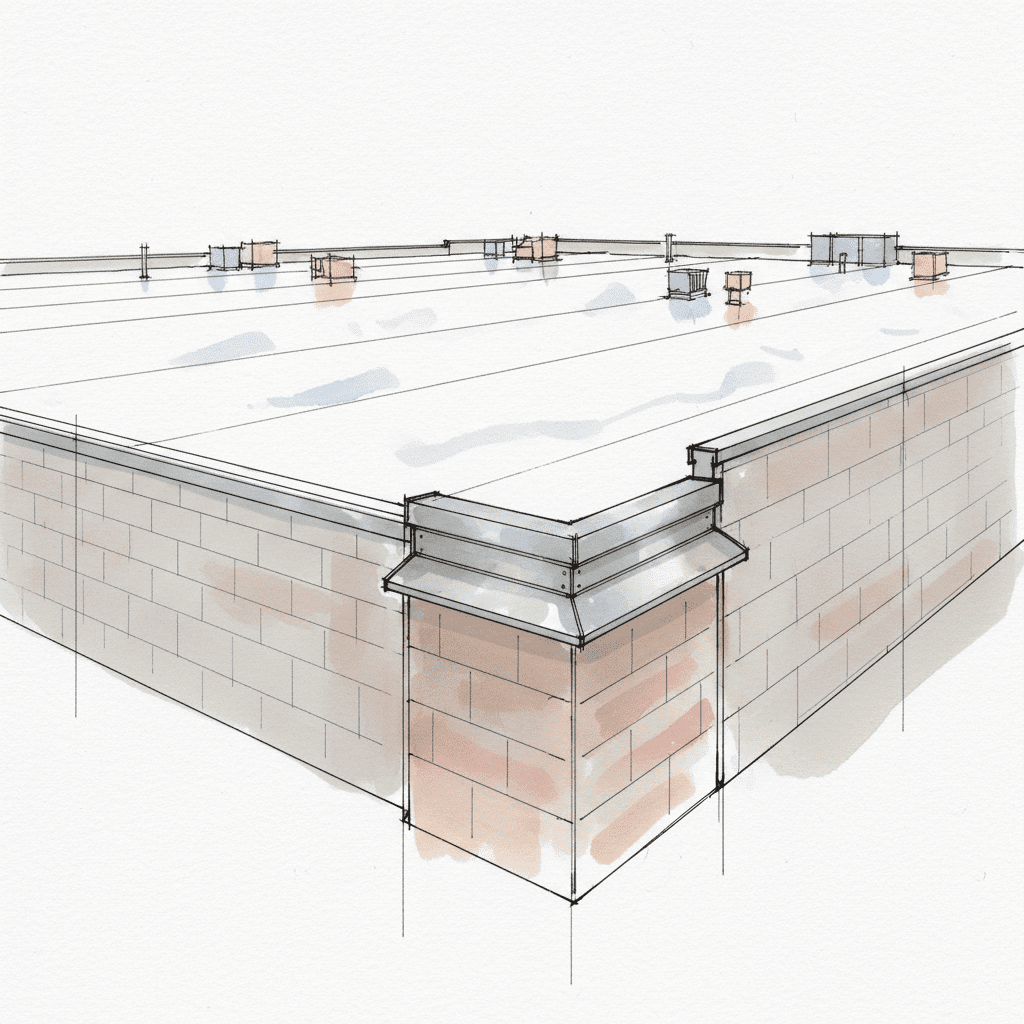

Parapet Wall Coping: The Capstone of Your Building Envelope Security

Parapet wall coping is the metal cap that protects the top of the wall. A low-cost, face-fastened coping is a primary failure point. Our methodology requires a system utilizing a continuous cleat on the front and back of the wall, with a concealed splice plate at each joint. This design secures the coping without penetrating the horizontal surface, allows for thermal movement without fatiguing the metal, and creates a fully sealed, watertight capstone for your building. This is the only responsible way to protect the integrity of the parapet wall and the roof membrane termination below it.

Gravel Stop and Drip Edge Systems: Mandating Proper Water Diversion

Gravel stop and drip edge profiles are installed at the roof edge where there is no parapet wall. Their function is to provide a finished, sealed termination for the roof membrane and to direct water into the gutters or away from the building facade. The critical detail is the outward-projecting flange, or drip edge, which prevents water from clinging to the underside of the metal and running down the face of the building. This prevents facade staining and long-term moisture damage to the wall assembly. We ensure the gauge of the metal and the dimension of the flange are engineered for the specific wind zone and rainfall expectations of your property.

Integrated Fascia and Flashing Systems: Aesthetics and Performance

Metal fascia systems provide a clean architectural appearance but must be engineered for performance. Our specifications demand a continuous cleat or retainer system for attachment. This is fundamentally different from the common practice of driving fasteners directly through the face of the metal. Face-fastened systems create hundreds of penetration points, allow for water intrusion, and are highly susceptible to fastener pull-out during wind events and thermal cycling. Our process ensures the fascia is locked into place, providing superior wind resistance and a flawless finish free of exposed fasteners.

ANSI/SPRI ES-1 Compliance: A Non-Negotiable Standard for Risk Management

The ANSI/SPRI ES-1 standard, titled “Wind Design Standard for Edge Systems Used with Low Slope Roofing Systems,” is not a suggestion; it is the industry’s legally recognized benchmark for performance. Adherence to this standard is a primary tool for risk management and a cornerstone of our fiduciary approach to commercial roofing.

Decoding Wind Resistance Ratings and Required Test Protocols

ES-1 establishes test protocols that rate edge metal systems based on their ability to resist wind uplift forces. Systems are tested by certified, independent laboratories and assigned ratings such as RE-1, RE-2, and RE-3, which correspond to specific levels of negative pressure resistance. Our process begins by calculating the required wind uplift rating for your specific building based on its geographic location, height, and exposure category. We then select and install a pre-certified system guaranteed to meet or exceed that requirement, providing you with documented, third-party proof of compliance.

Liability and Insurance Ramifications of ES-1 Non-Compliance

Installing a non-ES-1 compliant edge metal system is a material breach of your due diligence. After a major storm, insurance adjusters actively look for this compliance failure as grounds to deny a claim. They correctly argue that the damage was not the result of an unavoidable weather event, but of a substandard installation that failed to meet the recognized engineering standard. This leaves you, the asset owner, with the full financial burden of the loss. Conversely, providing documentation of an ES-1 compliant system streamlines the claims process and protects you from allegations of negligence, securing your insurance coverage when you need it most.

Verification Protocols for Contractor Adherence to ES-1 Standards

Simply stating that a system is “ES-1 compliant” is insufficient. Fiscal certainty requires verification. Our standard operating procedure includes a rigorous verification protocol:

- Submittals: We provide detailed shop drawings and manufacturer data sheets for the specified ES-1 system for your records before any material is ordered.

- Shop Drawings: These drawings explicitly detail the fabrication of the metal, the gauge, the cleat system, and the fastener patterns required to achieve the certified rating.

- Quality Control: Our project managers conduct phased inspections during installation to ensure our crews are adhering to the specifications with zero deviation. This documented process provides an unbroken chain of custody from specification to final installation.

Material Science and Lifecycle Cost Analysis for Edge Metal

The selection of edge metal material directly impacts the long-term financial performance of your roofing asset. A decision based solely on initial capital expenditure often results in a higher total cost of ownership (TCO) due to premature failure and increased maintenance. Our role is to guide you through a value-based analysis that balances upfront cost with long-term durability and risk mitigation.

Comparative Analysis: G-90 Galvanized Steel, Aluminum, and Stainless Steel

Each material possesses distinct performance characteristics that must be aligned with the building’s environment and the owner’s financial objectives. A low-cost material in the wrong application is a guaranteed liability.

| Material | Initial CapEx | Corrosion Resistance | Lifecycle Expectancy | Fiduciary Recommendation |

|---|---|---|---|---|

| G-90 Galvanized Steel | Low | Good (Relies on coating) | 15-25 Years | Suitable for standard environments; requires Kynar finish for warranty and performance. |

| Aluminum | Medium | Excellent (Naturally passive) | 30-50+ Years | Standard for coastal or corrosive industrial environments; higher thermal movement must be engineered for. |

| Stainless Steel | High | Superior | 50+ Years | Specified for critical infrastructure or where long-term asset preservation is the sole priority. |

Engineering for Thermal Expansion and Contraction to Prevent Failure

All metals expand and contract with temperature changes. This thermal cycling places immense stress on fasteners and sealants. A system that does not account for this movement will inevitably fail. Fasteners will loosen, holes will elongate, and sealant beads will break, creating pathways for water intrusion. Our engineering protocols mandate specific details, such as concealed splice plates with sealant bonds and slotted fastener holes, that allow the system to move without compromising its integrity. This preemptive engineering prevents the most common cause of non-storm-related edge metal failure.

Calculating TCO: Balancing Initial CapEx with Long-Term Asset Durability

The Total Cost of Ownership extends far beyond the initial installation price. It includes maintenance costs, repair costs, and the financial risk of failure and operational downtime. While a heavier gauge aluminum system with a Kynar finish may have a higher initial CapEx than a basic galvanized steel option, its significantly longer lifespan and superior performance can deliver a lower TCO over the holding period of the asset. We provide a clear TCO projection to help you make a data-driven capital planning decision that aligns with your financial strategy, rather than a short-sighted choice based on a contractor’s bid.

The RocStout SOP: A Framework for Fiscal Certainty and Zero-Defect Installation

The primary source of risk in any construction project is contractor negligence and a lack of process control. The RocStout Standard Operating Procedure (SOP) is designed to eliminate this risk. We replace guesswork and shortcuts with a rigid, documented methodology that ensures predictable outcomes, zero tenant disruption, and absolute fiscal certainty for your capital project.