Regular gutter and scupper maintenance is a non-negotiable risk management protocol designed to protect a commercial building’s structural integrity, mitigate liability, and preserve its capital asset value. It is the engineered process of ensuring the controlled, unimpeded evacuation of water from a low-slope roof system. As a fiduciary partner in asset management, we view deferred maintenance not as a potential cost but as a guaranteed future liability—one that manifests in foundational damage, inventory loss, and operational disruption. Choosing the lowest-cost provider for this critical function is a direct path to escalating capital expenditures and avoidable legal exposure. Our approach is engineered for one purpose: to deliver fiscal certainty and protect your asset from the predictable consequences of water mismanagement.

The Financial Liability of Deferred Gutter Maintenance

As a fiduciary for your property, your primary mandate is to maximize asset value while minimizing risk. Neglecting the building’s water management system is a direct contradiction of this mandate. The consequences of clogged or failing gutters and scuppers are not minor inconveniences; they are significant financial events that impact your balance sheet through emergency CapEx, insurance claims, and lost revenue.

Mitigating Foundational Damage and Structural Compromise

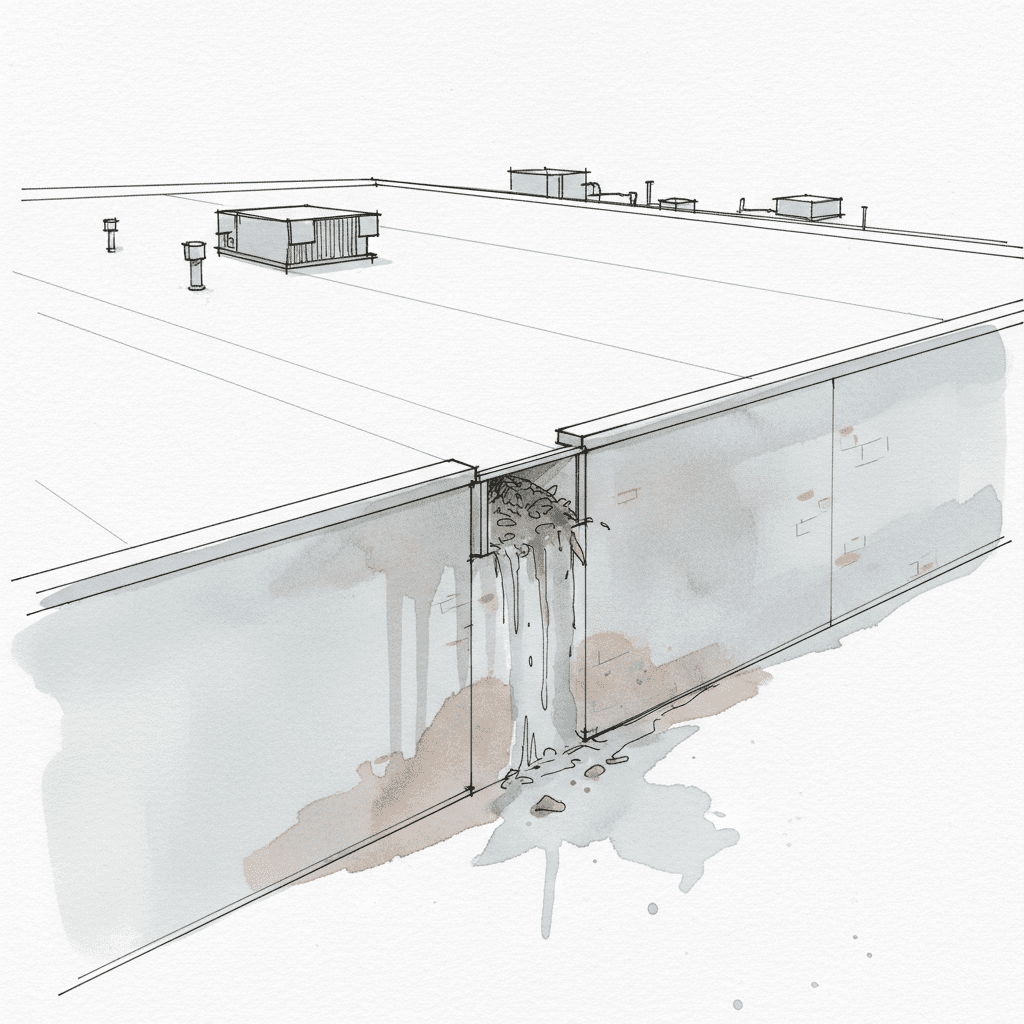

A low-slope roof’s drainage system is the first line of defense for the building’s foundation. When gutters and downspouts fail to channel thousands of gallons of water away from the structure, that water saturates the soil directly against the foundation walls. This triggers a cascade of costly structural failures. The oversaturated soil loses its load-bearing capacity and creates hydrostatic pressure, leading directly to foundation cracks, slab settlement, and visible masonry damage like spalling and efflorescence. What begins as a clogged gutter rapidly transforms into a multi-thousand-dollar structural engineering problem, an entirely unbudgeted and avoidable capital expenditure.

Preventing Water Ingress, Inventory Loss, and Tenant Disruption

When water cannot exit the roof via its designed pathway, it will find an alternative. On a low-slope roof, this means water pools against parapet walls, flashings, and seams—the most vulnerable points of the roofing membrane. This hydrostatic pressure accelerates the degradation of sealants and adhesives, inevitably causing water ingress. The results are immediate and severe: damaged inventory, ruined ceiling tiles, and the onset of mold growth, which requires specialized and costly remediation. More damaging, however, is the operational disruption. Leaks force tenant relocation, halt business operations, and generate complaints that can jeopardize lease agreements. The cost of a single day of downtime often exceeds the cost of a multi-year proactive maintenance program.

Ensuring Compliance with Building Codes and Insurance Mandates

Your commercial property insurance is not a maintenance plan; it is a policy that presupposes professional due diligence. Insurers can and will deny claims for water damage if evidence of neglect, such as clogged drainage systems, is discovered. Furthermore, property owners have a legal responsibility to maintain a safe premise. Water overflowing from clogged gutters can create hazardous ice patches on walkways and loading docks in winter, exposing your organization to significant premise liability and negligence claims. A professionally executed maintenance program, complete with detailed documentation and condition reports, serves as critical evidence of responsible asset management, ensuring policy compliance and insulating you from litigation.

Standard Operating Procedures for Commercial Gutter System Audits

RocStout does not perform ‘gutter cleaning’; we execute a systematic audit of your building’s complete water evacuation system. This is an engineering-led process designed to verify system performance, identify points of failure before they breach the building envelope, and provide the data necessary for long-term capital planning. We reject the ‘bucket and ladder’ approach of common contractors in favor of a documented, repeatable methodology.

Comprehensive Debris Removal and Flow-Rate Verification

Our standard operating procedure begins with the complete removal of all debris, sediment, and biological growth from all gutters, scuppers, and collector boxes. This is more than a simple cleaning; it is a prerequisite for accurate system analysis. Following debris removal, our technicians conduct water flow tests to verify that the system can handle the drainage volume for which it was engineered. This test immediately exposes hidden blockages in downspouts or underground leaders and confirms that water is being effectively channeled away from the foundation without impediment.

Seam, Joint, and Fastener Integrity Analysis

Commercial gutter systems are subjected to immense stress from thermal expansion and contraction. Our audit includes a meticulous, hands-on inspection of every seam, expansion joint, and fastener. We identify failing sealant, corrosion on fasteners, and gaps that are precursors to leaks. This proactive identification allows for scheduled, cost-effective repairs, preventing the emergency call that results from a full seam separation during a major weather event.

Downspout, Scupper, and Collector Box System Assessment

The audit extends beyond the horizontal gutter runs to the entire vertical drainage system. Technicians inspect downspout security, scupper box seals, and the integrity of leader heads or collector boxes. We verify that each component is securely fastened and properly sealed to the building envelope. Any signs of blockages, corrosion, or physical damage are documented with high-resolution photography, providing you with a clear asset condition report.

Roof Edge, Flashing, and Fascia Condition Evaluation

A gutter system is an integrated component of the overall roof edge assembly. Our technicians are trained to assess the condition of the adjacent roof membrane, metal flashing, coping caps, and fascia. We understand that a failing gutter can channel water behind the fascia, compromising the roof edge and creating a direct path for water infiltration into the building’s structure. This holistic evaluation ensures that we are not simply clearing a drain but preserving the integrity of the entire building envelope.

Developing a Proactive Maintenance Schedule for Fiscal Certainty

Reactive maintenance is the enemy of fiscal predictability. Our objective is to transition your roof asset management from an unpredictable expense category to a line-item in your annual operating budget. This is achieved through a data-driven maintenance schedule and long-range lifecycle planning.

Establishing Maintenance Frequency Based on Environmental Load and Asset Type

There is no one-size-fits-all maintenance schedule. A facility surrounded by mature deciduous trees faces a fundamentally different debris load than a warehouse in an open industrial park. RocStout develops a customized maintenance frequency—typically semi-annually or quarterly—based on a thorough assessment of your specific environmental factors. We analyze vegetation overhang, proximity to industrial pollutants, regional climate conditions, and the specific design of your roof’s drainage system to create a plan that delivers maximum value and risk mitigation without unnecessary expenditure.

Leveraging Documentation for Multi-Year Lifecycle Planning

Every service visit concludes with a detailed condition report that serves as a tool for your capital planning process. This is not an invoice; it is an asset management document. It provides a photographic log, a detailed summary of current conditions, and data-driven recommendations for future repairs or replacements. This documentation allows you to move from reactive spending to proactive, multi-year lifecycle planning, ensuring financial predictability.

| Asset Component | Current Condition (Example) | Estimated Remaining Service Life | Recommended Action | Budgetary Forecast (Year) |

|---|---|---|---|---|

| Gutter Seams (Sector B) | Minor sealant degradation | 1-2 Years | Budget for reseal in next fiscal cycle | Y+1 |

| Downspout (NW Corner) | Corrosion at base; loose anchor | < 1 Year | Immediate repair/replacement required | Current Qtr |

| Scupper Boxes (All) | Good; minor debris accumulation | 5+ Years | Continue semi-annual inspection | Operational Budget |

OSHA Compliance and Liability Mitigation in Maintenance Operations

Hiring a contractor to work at height on your property is a significant liability transfer. A low-bid, non-compliant contractor exposes your organization to immense financial and legal risk. RocStout operates under a strict, non-negotiable safety protocol that protects our team, your staff, and your business from liability. We view safety not as a matter of preference, but as a core component of professional service delivery.

Adherence to OSHA Fall Protection Standards (29 CFR 1926.501)

All RocStout operations are conducted in strict compliance with OSHA standards, specifically 29 CFR 1926.501 regarding fall protection. Before any work commences, a formal Job Safety Analysis (JSA) is performed to identify all potential hazards. Our technicians are equipped with and trained in the proper use of all necessary personal fall arrest systems (PFAS), including harnesses, lanyards, and anchorage points. Our commitment to compliance is your assurance that you will not be exposed to regulatory fines or litigation resulting from a contractor’s safety failures.

Minimizing Operational Disruption Through Strategic Scheduling and Communication

The true cost of any building maintenance is measured in operational disruption. Our process is engineered to be invisible to your tenants and operations. We achieve this through a rigid communication and logistics protocol that ensures business continuity. This is how we protect your revenue while servicing your asset.

The RocStout Protocol: Engineering Predictability in Asset Management

Choosing a roofing and construction partner is a critical capital decision. RocStout operates as a fiduciary advisor, providing a process-driven methodology that transforms roof maintenance from a reactive liability into a predictable, managed asset. We do not compete on price; we compete on delivering absolute fiscal certainty and operational continuity.

Line-Item Reporting and ‘No Surprise’ Billing for Predictable Expenditures

We believe that financial transparency is the bedrock of a fiduciary relationship. Every proposal and invoice from RocStout provides line-item detail, ensuring you understand exactly what services are being performed and what value is being delivered. Our proactive maintenance programs are offered on a fixed-cost agreement basis, allowing you to budget with precision. There are no hidden fees, no ambiguous charges, and no surprise invoices. This is our commitment to providing predictable capital expenditure management.

A Process-Driven Methodology to Eliminate Tenant Disruption and Safety Risks

Our value is not just in the technical work we perform, but in the operational certainty we provide. Our project management, safety protocols, scheduling systems, and communication plans are all components of a single methodology designed to achieve a zero-incident, zero-disruption goal. By engaging RocStout, you are not merely hiring a contractor; you are partnering with a risk management firm that specializes in commercial building envelopes. We provide the professional authority and process-driven execution necessary for the responsible management of your commercial infrastructure.