Executive Summary: Core System Engineering and Financial Implications

The selection between an adhered and a mechanically fastened roofing system is a critical capital decision that directly impacts a building’s lifecycle cost, operational continuity, and liability profile. This is not a choice between adhesives and screws; it is a calculated trade-off between initial expenditure, long-term performance, and risk tolerance. As fiduciary advisors in commercial asset protection, our standard is to engineer a roofing solution that aligns with your financial objectives, ensuring the specified system serves as a predictable, high-performance asset, not an escalating liability. Choosing the lowest bidder for a commercial roof is a direct invitation to operational disruption, tenant litigation, and catastrophic asset failure. We provide fiscal certainty through engineered precision.

Technical Deep Dive: Adhered (Fully Adhered) Roofing Systems

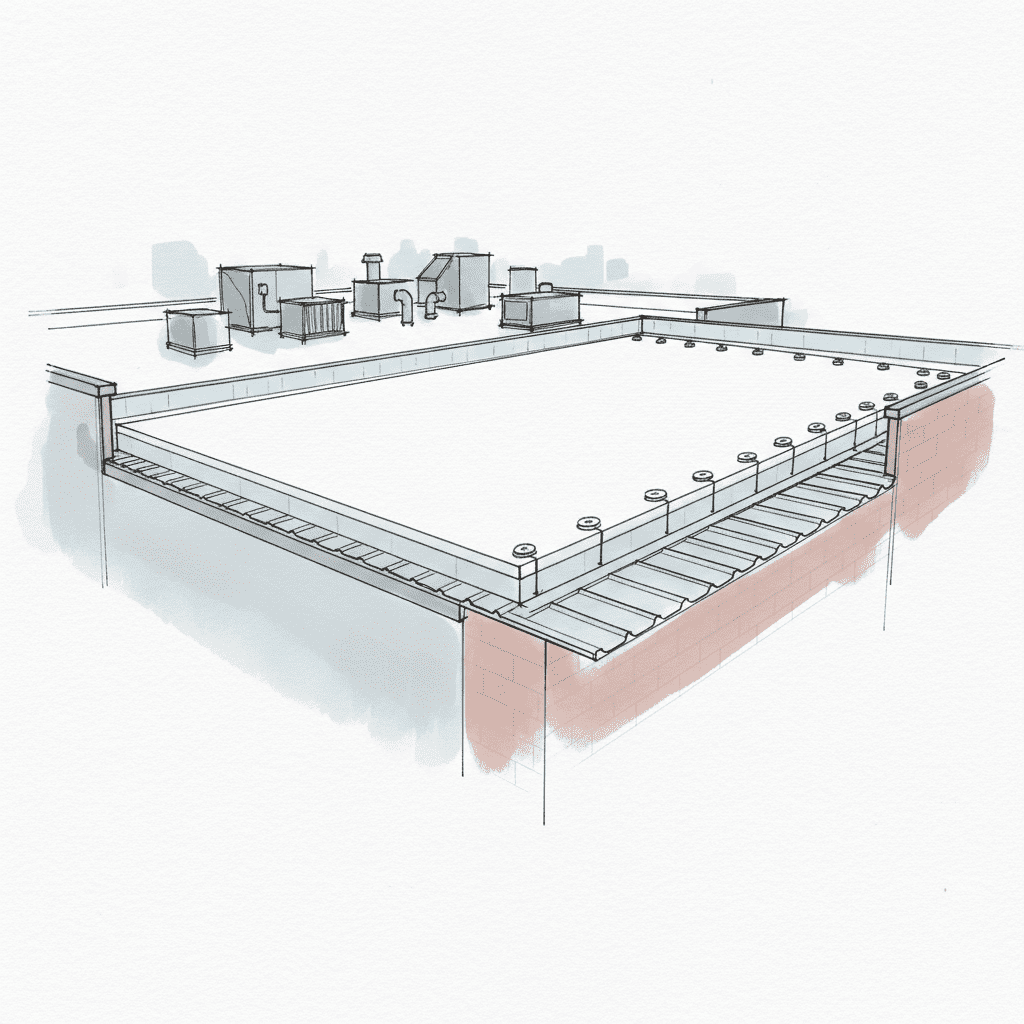

A fully adhered roofing system involves bonding the insulation and membrane directly to the roof substrate using specialized, high-strength adhesives. This methodology creates a continuous, monolithic barrier that fully integrates with the building structure, providing a seamless and highly durable weatherproofing layer. The success of this system is contingent upon meticulous substrate preparation and environmental condition management during installation, factors that our Standard Operating Procedures (SOPs) rigorously control.

Component Analysis: Substrate, Adhesives, and Membrane Integrity

The integrity of a fully adhered system is a direct function of the chemical bond between three components: the structural deck, the insulation boards, and the waterproofing membrane (typically TPO, PVC, or EPDM). The substrate must be pristine—clean, dry, and structurally sound—to achieve the requisite adhesion strength. We utilize advanced bonding adhesives, including low-odor and low-VOC (Volatile Organic Compound) formulations, to minimize tenant disruption and ensure compliance with environmental and safety regulations. The membrane itself is then fully bonded, eliminating the potential for sheet movement and ensuring uniform structural support.

Performance Profile: Wind Uplift Resistance and Monolithic Weatherproofing

From a risk management perspective, the primary engineering advantage of a fully adhered system is its exceptional wind uplift resistance. By creating a continuous bond across the entire roof surface, wind load is distributed evenly, eliminating the stress concentration points inherent in mechanically fastened systems. This results in a monolithic seal that is less susceptible to wind-induced peeling or failure, a critical performance metric for buildings in high-wind zones or those with significant height. This seamless barrier also presents fewer opportunities for water intrusion, significantly reducing the risk of costly interior damage, mold proliferation, and operational downtime.

Technical Deep Dive: Mechanically Fastened Roofing Systems

Mechanically fastened systems secure the roofing membrane and insulation to the structural deck using a specific pattern of engineered fasteners and plates. This method is often faster and less dependent on weather conditions during installation, which can be a factor in project scheduling. However, this efficiency introduces distinct performance variables and potential long-term financial liabilities if not engineered and executed with absolute precision.

Component Analysis: Fastener Patterns, Plates, and Structural Deck Interface

The performance of a mechanically attached roof is dictated by the engineering of its fastening system. This includes fastener type, fastener density, and plate design, all calculated based on pull-out resistance tests of the specific structural deck (e.g., steel, concrete, wood). A higher fastener density is required in perimeter and corner zones where wind uplift forces are greatest. We specify corrosion-resistant fasteners and stress plates to ensure the long-term integrity of each attachment point, as a single point of failure can compromise the entire roof envelope.

Performance Profile: Mitigating Thermal Bridging and Membrane Flutter

Every fastener in a mechanically attached system creates a point of thermal bridging—a direct path for heat to escape or enter the building. This accumulation of hundreds or thousands of penetration points degrades the overall R-value of the insulation, translating directly to higher year-over-year energy costs (OpEx). Furthermore, the membrane is only secured at the fastener points, leaving loose areas that can “flutter” under wind load. This constant movement causes fatigue and premature wear, particularly at the seams, increasing the probability of future leaks and the need for unplanned capital repairs.

Comparative Financial Analysis: A 20-Year Lifecycle Cost Model

A responsible capital plan evaluates roofing not on initial price, but on Total Cost of Ownership (TCO). A lower initial CapEx can often conceal significantly higher long-term OpEx, repair costs, and liability exposure. Our analysis focuses on providing fiscal certainty over the full asset lifecycle.

| Financial Metric | Fully Adhered System | Mechanically Fastened System |

|---|---|---|

| Initial CapEx | Higher (Intensive labor, adhesive cost, substrate prep) | Lower (Faster installation, less weather dependency) |

| Energy Efficiency (OpEx) | Superior (No thermal bridging, continuous insulation) | Compromised (Thermal bridging at each fastener reduces R-value) |

| Maintenance & Repair Costs | Lower (Monolithic surface, fewer penetration points to fail) | Higher (Vulnerable to fastener back-out and seam fatigue from flutter) |

| Asset Lifespan | Longer (Uniform support, less membrane stress) | Shorter (Increased wear from membrane movement and stress points) |

| Total Cost of Ownership | Often Lower over 20+ years | Often Higher due to energy loss and repair cycles |

Initial Capital Expenditure (CapEx): Labor, Materials, and Installation Time

Mechanically fastened systems typically have a lower initial capital outlay due to faster installation and reduced material costs (adhesives vs. fasteners). However, adhered systems, while more labor-intensive and weather-dependent (requiring specific temperatures and dry conditions for adhesive curing), represent a more robust initial investment in the building envelope’s long-term performance.

Long-Term Operating Expenses (OpEx): Maintenance, Repairs, and Energy Efficiency

This is where the financial models diverge significantly. The absence of thermal bridging in an adhered system delivers quantifiable energy savings year after year. Conversely, a fastened system carries a baked-in energy penalty for the life of the asset. Furthermore, the thousands of penetrations in a fastened roof are all potential failure points that require diligent preventive maintenance to mitigate. An adhered system, with its seamless surface, inherently reduces this long-term repair liability.

Warranty and Liability: Understanding Manufacturer vs. Contractor Coverage

A manufacturer’s warranty (even an NDL, or No Dollar Limit warranty) primarily covers material defects. It will not cover failures resulting from improper installation or faulty workmanship—the most common cause of roof failure. This is the liability gap where facility owners are most exposed. RocStout’s comprehensive workmanship guarantee is designed to close this gap, ensuring that the engineered specification is executed flawlessly. We stand behind the total system performance, providing a single point of accountability and insulating your capital investment from finger-pointing between a manufacturer and a low-bid contractor.

Operational Risk Assessment: Mitigating Tenant Disruption and Safety Hazards

The true cost of a roofing project must account for its impact on business operations. Operational continuity is paramount, and the choice of installation method directly influences noise levels, safety protocols, and overall disruption to tenants and employees.

Acoustic Disruption Analysis: Installation Noise Impact on Building Occupants

The installation of a mechanically fastened system involves the continuous, high-decibel noise of drills securing thousands of fasteners into the structural deck. This acoustic disruption is a significant issue for occupied buildings such as offices, medical facilities, and multi-tenant commercial properties. Adhered systems, which primarily utilize rollers and low-noise adhesive applicators, are substantially quieter, preserving a productive work environment and eliminating a primary source of tenant complaints.

Installation Schedule & Site Logistics: Adhered vs. Fastened Timelines

While mechanically fastened systems can be installed more quickly under ideal conditions, their logistics involve managing thousands of small components (screws and plates). Adhered systems require more meticulous planning around material staging and weather windows. Our project management protocol mitigates this risk through precise scheduling, real-time weather monitoring, and clear communication, ensuring schedule certainty and minimizing the time your building is under active construction.

Code Compliance and Wind Engineering: Specifying for Regional Liabilities

Specification is not a matter of preference; it is a matter of compliance and engineering. We design systems to meet or exceed the most stringent building codes and insurance underwriting standards, such as those from FM Global and ASCE 7. This is not about checking a box; it is about ensuring the survivability of the asset in a severe weather event and securing favorable insurance terms.

Navigating FM Global and ASCE 7 Standards for High-Wind Zones

For facilities in designated high-wind zones or those of a certain height, adherence to FM Global or ASCE 7 standards is non-negotiable. These standards dictate precise requirements for wind uplift resistance, which often favor the performance profile of a fully adhered system. Our engineering process includes a full analysis of your building’s location, height, and geometry (including parapet walls) to specify a system that is fully compliant and insurable.

Substrate Compatibility: The Critical Factor in System Specification and Longevity

The single most critical variable in system selection is the condition and type of the existing structural deck. An adhered system requires a compatible and sound substrate to form a proper bond. Attempting to adhere a membrane to a deteriorating or incompatible deck is an engineered failure. A mechanically fastened system’s performance depends on the deck’s ability to provide adequate fastener pull-out resistance. Our mandatory pre-project forensic analysis, including core sampling and pull-out tests, validates substrate compatibility, eliminating the risk of system failure due to a mismatched specification.

The RocStout Protocol: Engineering Fiscal Certainty in Roof Asset Management

We operate as fiduciary partners, not contractors. Our structured protocol transforms a reactive, unpredictable roofing expenditure into a managed, predictable component of your capital plan. We do not compete on the initial bid; we compete on delivering the lowest Total Cost of Ownership and zero operational disruption.

Our System Specification Process: A Data-Driven Approach to Capital Planning

We reject guesswork. Our process begins with a comprehensive forensic analysis of your existing roof asset. Through core sampling, infrared moisture surveys, and structural assessments, we gather the quantitative data required to model long-term performance and lifecycle costs. The result is a detailed specification document that provides line-item transparency and a clear recommendation engineered to meet your financial goals, whether that be maximizing ROI for a long-term hold or optimizing performance for a near-term sale.

Executing with Precision: Minimizing Operational Disruption Through SOPs

Our value proposition is realized through disciplined execution. Every RocStout project is managed by a dedicated project manager who enforces our strict Standard Operating Procedures. This includes a proactive tenant communication plan to inform occupants of work schedules, rigorous safety protocols that exceed OSHA requirements to eliminate site liability, and daily progress reports to ensure absolute schedule adherence. We deliver fiscal certainty through operational excellence, ensuring a seamless project with no change orders and no surprise billing. This is the standard of care required for managing high-value commercial assets.