Introduction: Defining Attic Ventilation as a System, Not a Feature

Attic ventilation is a building science system designed to create a continuous, balanced flow of air through the attic space. This system functions by pairing low intake vents with high exhaust vents to manage temperature and mitigate moisture accumulation. It is an engineered control mechanism, not an optional feature or an aesthetic choice. The functional integrity of your roof, the structural components it protects, and the overall energy efficiency of your home are directly dependent on its correct implementation.

A properly engineered ventilation system is a non-negotiable component of long-term asset protection. It is the primary defense against the systemic failures caused by uncontrolled heat and moisture. The consequences of an improperly specified or installed system are not minor inconveniences; they are catastrophic breakdowns that include structural rot, pervasive mold, and premature roof failure. These outcomes are the direct result of a chaotic, low-bid approach to roofing that prioritizes speed over precision.

RocStout Roofing and Construction operates on a principle of meticulous engineering. We design and install roofing systems built for predictable, long-term performance. This requires a level of analysis, material specification, and execution that is fundamentally incompatible with a lowest-price model. If your primary decision metric is the lowest initial bid, we are not the right partner for your project. Our clients are meticulous homeowners who understand that a higher initial investment in a correctly engineered system is the only logical path to eliminating the costly, chaotic failures common in our industry.

The Physics of Airflow: How a Ventilated Attic Functions

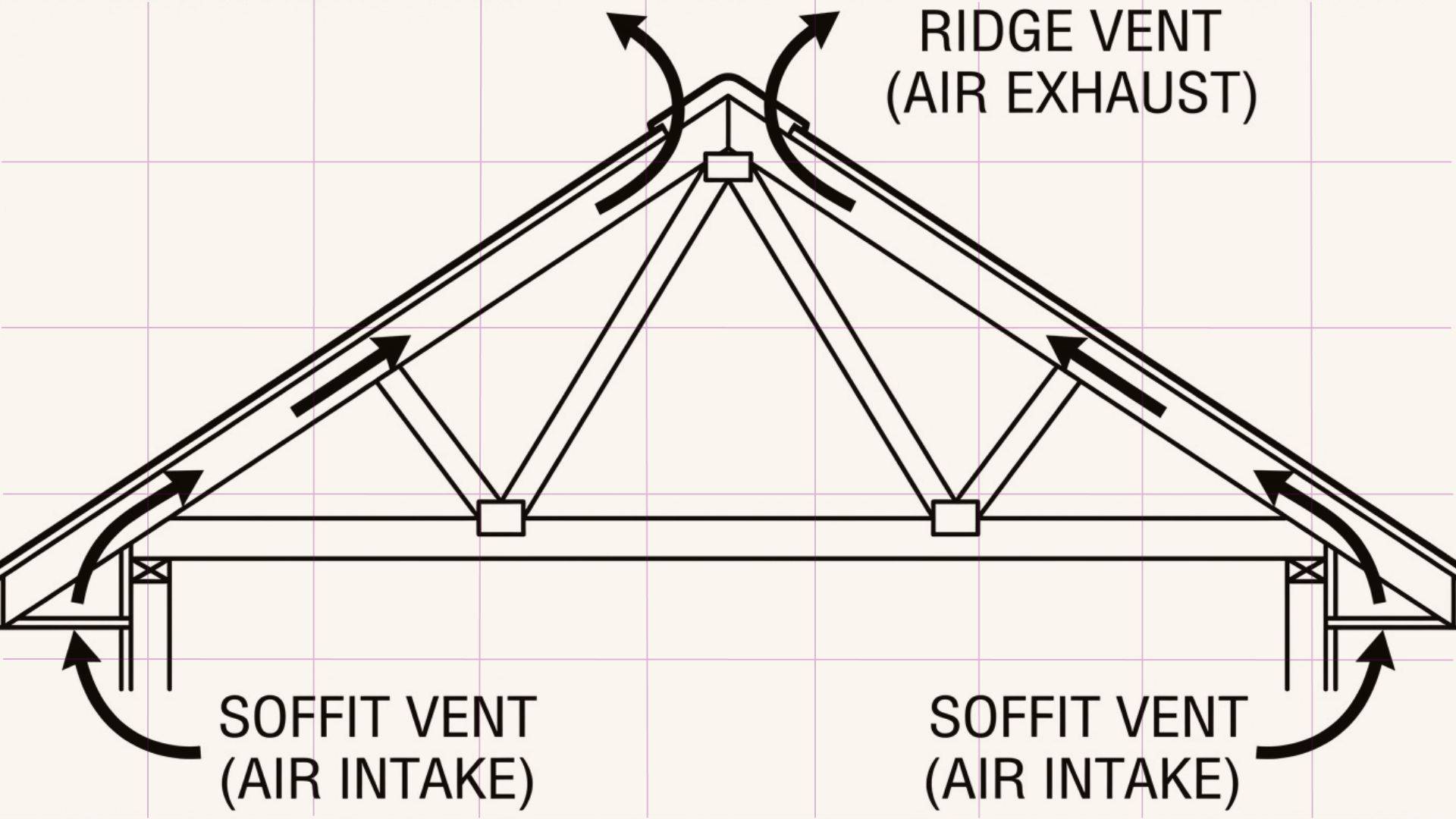

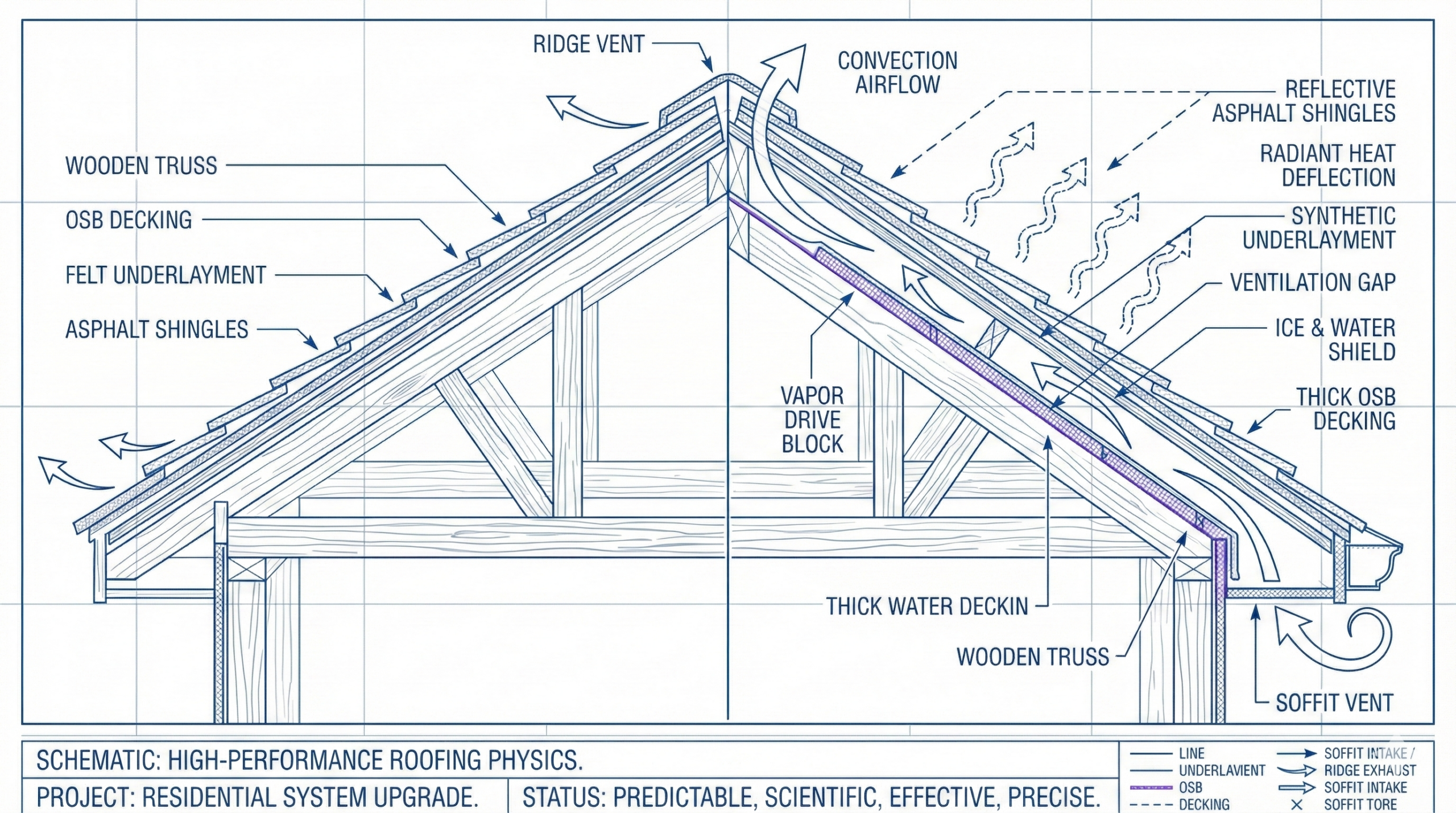

A passive attic ventilation system operates on two core principles of physics. It does not require mechanical fans or energy inputs. It leverages natural forces to create a predictable and constant exchange of air. Understanding these principles is essential to diagnosing system failures and appreciating the necessity of a balanced design.

Principle 1: Thermal Buoyancy (The Stack Effect)

Thermal buoyancy, or the stack effect, is the physical principle that less dense, warm air rises while cooler, denser air sinks. Inside an attic, solar radiation heats the air, causing it to expand and become less dense. This warm, buoyant air rises to the highest point of the attic. Exhaust vents, such as a ridge vent, located at the peak of the roof allow this air to escape. The escaping air creates a negative pressure zone within the attic, which in turn pulls cooler, denser ambient air into the attic through intake vents, such as soffit vents, located at the lowest point of the roof eaves. This process creates a continuous, passive convective loop that flushes heat and moisture out of the attic.

Principle 2: Wind Effect (Venturi Effect)

The wind effect supplements the thermal buoyancy process. As wind moves across the peak of a roof, it creates a small area of low pressure directly above the exhaust vents, a phenomenon consistent with the Venturi effect. This low-pressure zone acts as a siphon, actively pulling the warm air out of the attic at an accelerated rate. The stronger the wind, the more powerful the siphoning effect becomes. This principle ensures the ventilation system remains effective even on overcast days when solar heat gain, the driver of the stack effect, is minimal. A properly designed system leverages both principles to guarantee consistent airflow under a wide range of weather conditions.

The Primary Threats Mitigated by Proper Ventilation

A non-existent or malfunctioning attic ventilation system exposes your home to a cascading series of failures. These are not possibilities; they are eventualities. The system’s sole purpose is to neutralize these specific, destructive threats to your primary financial asset.

Threat 1: Moisture Accumulation and Its Consequences

A typical family of four generates two to four gallons of water vapor per day through activities like cooking, showering, and respiration. This moisture-laden air rises and infiltrates the attic space. In a poorly ventilated attic, this vapor becomes trapped. As the roof deck cools overnight, the trapped vapor condenses from a gas into liquid water, saturating insulation and wooden structural members. This chronic dampness is the perfect environment for destructive biological growth and material degradation.

- Sheathing Delamination: Plywood or OSB roof sheathing absorbs moisture, causing the wood layers and adhesives to swell and separate, losing all structural integrity.

- Truss and Rafter Degradation: Persistent moisture leads to wood rot, compromising the load-bearing capacity of the entire roof frame.

- Insulation Compaction: Wet insulation becomes compressed and matted, drastically reducing its R-value and rendering it ineffective for thermal resistance.

- Fungal Growth: Mold and mildew proliferate on damp organic surfaces, posing a significant health hazard to occupants and causing irreversible material damage.

Threat 2: Shingle Degradation from Excessive Heat

An unventilated attic in direct sunlight acts as a solar oven, with temperatures routinely exceeding 150°F. This superheated air radiates downward, baking the asphalt shingles from the underside. This constant thermal stress systematically destroys the shingles by accelerating the loss of their volatile chemical components, which are essential for flexibility and water resistance. The result is a drastically shortened lifespan and premature, catastrophic failure.

The specific mechanisms of failure include thermal blistering, where trapped moisture within the shingle vaporizes and creates bubbles, and accelerated granule loss, where the protective ceramic granules detach from the heat-softened asphalt. The shingles become brittle, crack, and cease to function as a waterproofing layer. This is not normal wear; it is a preventable failure caused by a deficient ventilation system, a hallmark of low-cost, corner-cutting installations.

Threat 3: Ice Damming in Cold Climates

Ice damming is a predictable system failure, not a random act of nature. It occurs when a poorly ventilated and insulated attic allows heat from the living space to warm the underside of the roof deck. This heat melts the snow on the roof from below. The meltwater runs down the roof surface until it reaches the cold eaves, which are not warmed by the attic heat. There, the water refreezes, forming a ridge of ice—the ice dam. Subsequent meltwater pools behind this dam, submerging the lower courses of shingles. This standing water forces its way under the shingles and through the roof deck, causing severe water damage to the attic, insulation, ceilings, and walls.

The process is a clear, linear chain of failure.

Interior damage, mold growth, and structural rot.

A properly ventilated attic keeps the roof deck temperature consistent and close to the outside air temperature. This prevents the initial snow melt, breaking the chain of events before the ice dam can form. It is a proactive, engineered solution to a chaotic and destructive problem.

Calculating Ventilation Requirements: The RocStout Process

The standard roofing industry often relies on simplistic rules of thumb and guesswork to specify ventilation. This approach is a primary source of system failure. It introduces an unacceptable level of risk and unpredictability. RocStout eliminates this chaos by employing a methodical, data-driven process to engineer a ventilation system specific to the unique parameters of your home.

The 1/300 Rule: Why Balance Matters

Building codes often cite a baseline ventilation requirement known as the 1/300 rule (1 square foot of ventilation for every 300 square feet of attic space). While this is the industry standard, simply having vents isn’t enough—they must be balanced between intake (soffit) and exhaust (ridge). Improper ventilation can trap heat and moisture, which is the leading cause of premature shingle failure. At RocStout, we ensure your replacement roof includes the proper ventilation components required to protect your home and keep your shingle manufacturer’s warranty valid.

Critical Variables We Consider

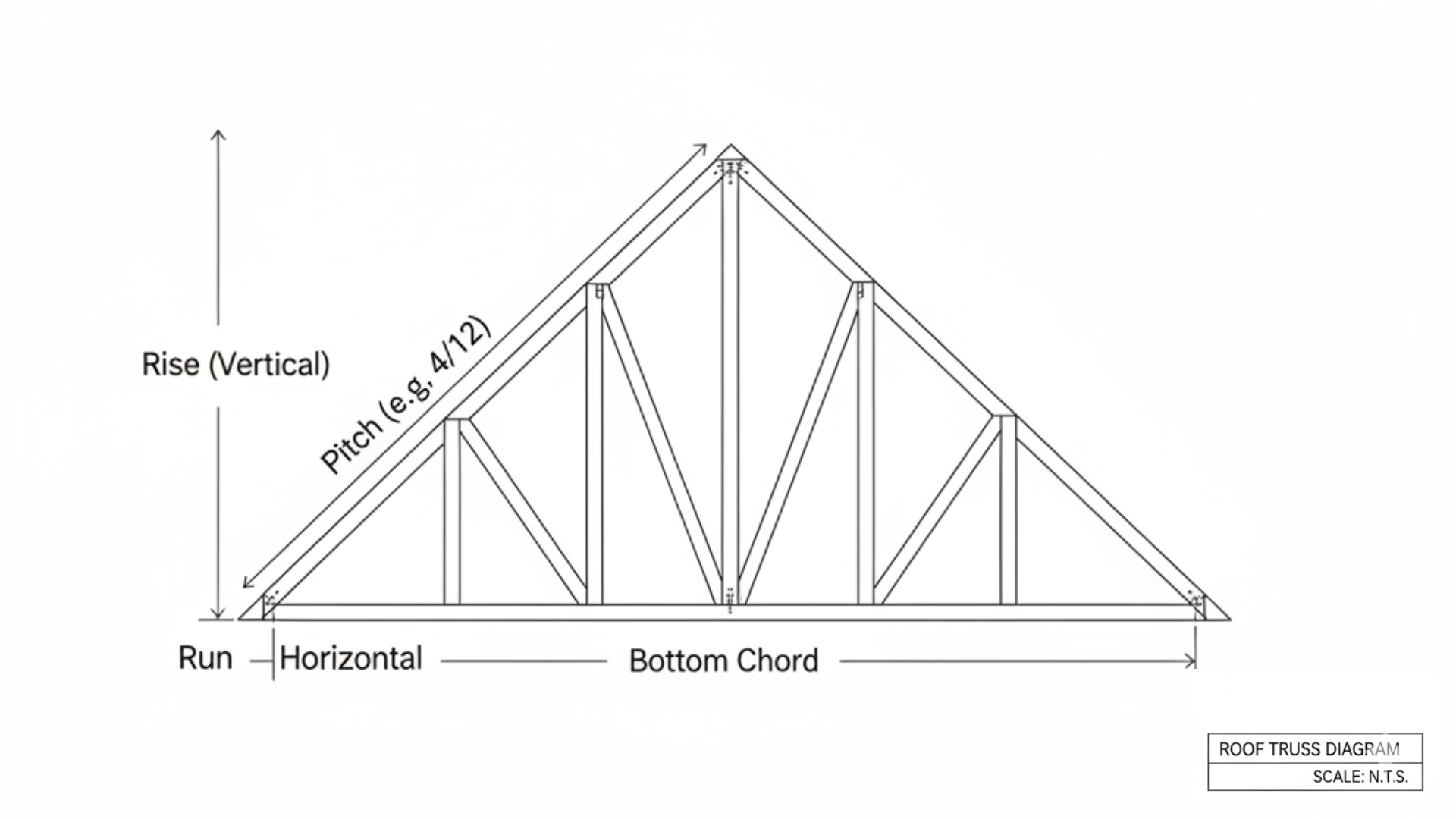

We view the 1/300 rule as a baseline, but true system longevity comes from understanding the specific conditions of your home. We assess the factors that impact heat and moisture loads to ensure the chosen system performs efficiently in the real world, not just on paper.

-

Roof Pitch and Geometry: Steeper pitches and complex layouts (hips and valleys) can create “dead air pockets” where heat gets trapped. We strategically place exhaust vents to encourage consistent airflow across the entire attic space, rather than just the center.

-

Climate Zone: Our region’s specific humidity and temperature swings demand robust moisture control. We ensure the selected products are designed to handle local weather patterns rather than generic national standards.

-

Insulation & Intake Hygiene: Even the best ventilation fails if insulation blocks the airflow. We verify that soffit vents are clear and properly baffled, ensuring the “lungs” of the house aren’t choked off by attic insulation.

-

Solar Exposure: Darker roofs and south-facing slopes absorb significantly more heat. For these high-exposure assets, ensuring uninhibited airflow is critical to preventing premature shingle aging.

Achieving a Balanced System: Intake vs. Exhaust

he most critical element of a functional roof is the balance between intake (soffit) and exhaust (ridge) ventilation. A common mistake in the industry is installing powerful exhaust vents without ensuring there is enough intake air to feed them. The ideal system targets a 50/50 balance.

If there is insufficient intake, exhaust vents will starve for air and try to pull it from the path of least resistance. This often means pulling conditioned (expensive) air from your living space up through light fixtures and attic hatches. In extreme cases, this negative pressure can even cause backdrafting of water heaters. A RocStout installation prioritizes this intake-to-exhaust ratio to ensure the attic breathes from the outside, keeping your home safe and energy-efficient.

RocStout’s Commitment to Predictable Outcomes

Our entire process is designed to eliminate the variables that lead to failure, budget overruns, and homeowner stress. We do not guess. We calculate, we model, and we execute with precision. The meticulous specification of your attic ventilation system is a direct reflection of this philosophy. It is a core component of a holistic roofing system that delivers a predictable, stress-free outcome.

A properly ventilated attic is not an abstract technicality; it is the foundation of a low-maintenance, resilient home. It is your defense against the chaos of premature failure and emergency repairs. We are not selling a product; we are delivering an engineered solution that protects your primary asset. This level of diligence requires a commensurate investment. For clients who value order, predictability, and long-term security, the return on that investment is absolute peace of mind.

A RocStout ventilation system is a guarantee against the destructive forces of moisture, heat, and ice. It is the only rational approach for a homeowner who demands control and refuses to leave the integrity of their home to chance.